Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

Fiber Optic Tools Manufacturer

Fiber optic networks require specialized equipment and tools for installation, splicing, testing, and maintenance. These tools ensure precise handling of delicate fibers, optimal signal transmission, and long-term reliability.

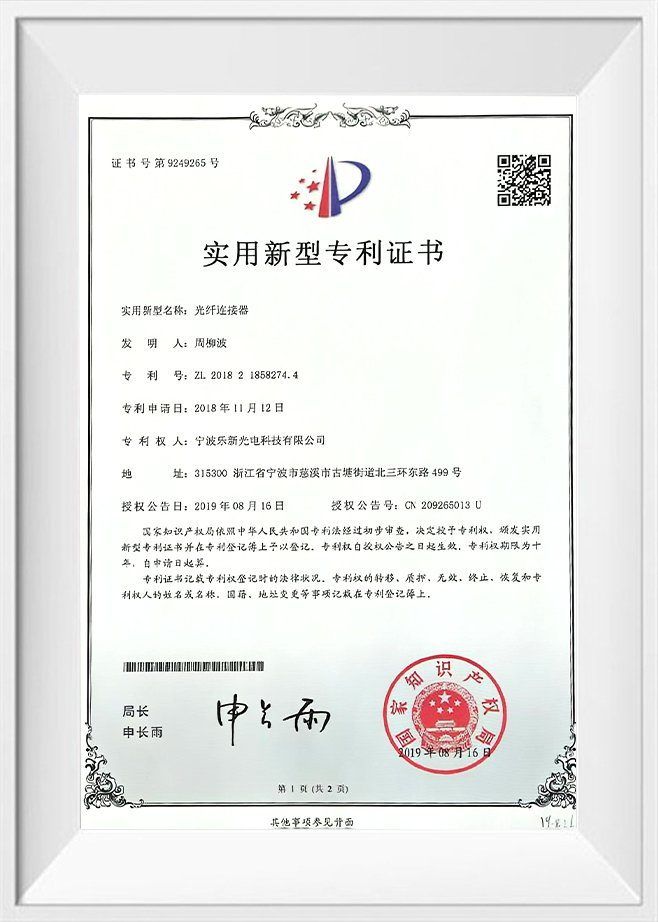

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Wholesale Fiber Optic Tools Manufacturer and OEM Fiber Optic Equipment&Tool Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Jan 03, 2026_GoshiningIn modern fiber optic network cabling, the LC fiber optic fast connector has become a core component in FTTH (Fiber to the Home) and data center construction due to its small size, low loss, and ease of operation. It allows for cold splicin...Read More

-

Dec 26, 2025_GoshiningIn fiber optic communication networks, especially in the large-scale construction of FTTH (Fiber to the Home), SC Fiber Optic Fast connectors (Field Assembly Connectors) have become indispensable key components. With advantages such as no f...Read More

-

Dec 19, 2025_GoshiningIn modern optical communication networks, the Optical Distribution Frame (ODF) is an indispensable core component. Whether in large data centers, telecommunications equipment rooms, or enterprise LANs, the ODF plays the role of a "traffic h...Read More

Professional fiber optic tools constitute the technical basis for the construction and maintenance of fiber optic networks, and are used in all aspects of fiber optic cabling, splicing, testing, and maintenance. Unlike ordinary electrical tools, fiber optic tools are designed for processing glass optical fibers with a diameter of only 125 microns. Their precision requirements reach the micron level, which is the key guarantee for ensuring the high performance and long life of fiber optic networks.

The core value of fiber optic tools is mainly reflected in three aspects: first, they realize the precise processing of fragile optical fibers to avoid microbends or breaks during installation; second, professional tools can minimize the signal loss at the fiber connection point to ensure the best optical transmission performance; finally, high-quality tools significantly improve construction efficiency and reduce operation and maintenance costs.

The fiber optic splicer is the core equipment with the highest technical content in the fiber optic tool system. Its working principle integrates precision machinery, optical imaging, and intelligent control technology. Modern splicers use core direct alignment technology, capture the image of the fiber end face through a high-resolution camera, use image processing algorithms to analyze the core position in real time, and then drive the precision V-groove by a piezoelectric ceramic motor to align the cores of the two optical fibers to an accuracy of less than 0.1 microns. Finally, the optical fiber is permanently fused together through a high-voltage arc at a high temperature of 1500-2000°C. The whole process takes only 8-15 seconds.