Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

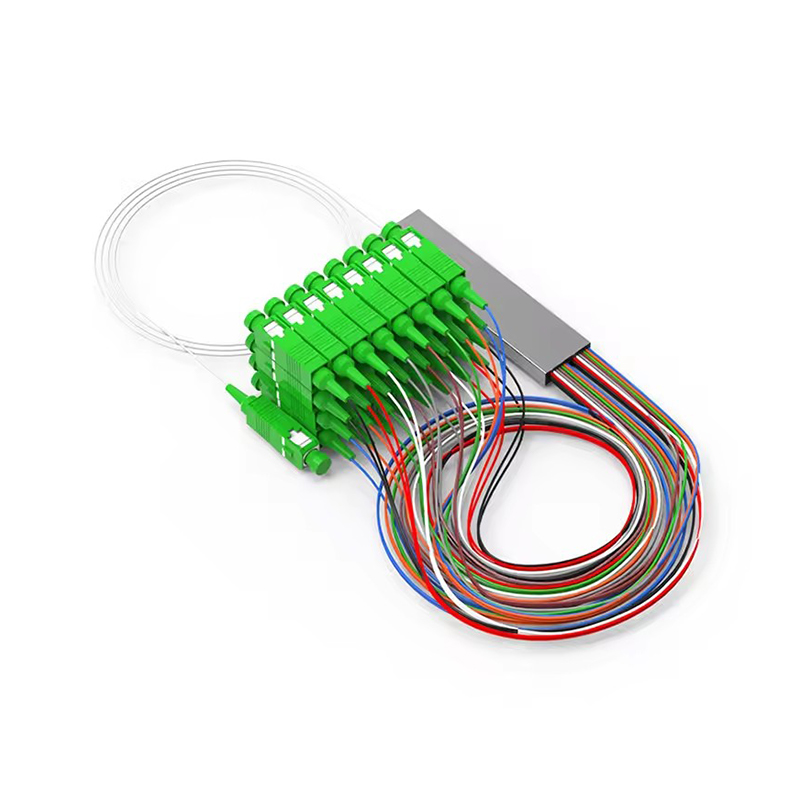

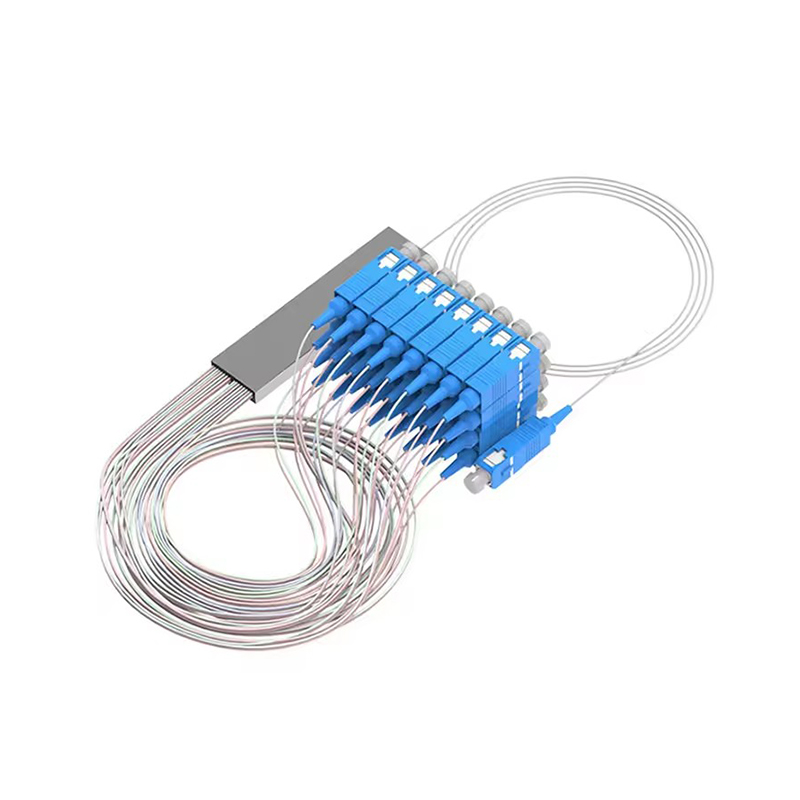

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

Fiber Optic PLC Splitter Supplier

Fiber Optic PLC (Planar Lightwave Circuit) Splitter is a passive optical device that evenly divides an input optical signal into multiple output signals (or combines multiple signals into one). It is a key component in PON (Passive Optical Network) systems like GPON, EPON, and XGS-PON, enabling efficient FTTH (Fiber-to-the-Home) deployments.

Common Form Factors: Bare Fiber (Mini Module), ABS Box Type, LGX Cassette, and Rack-Mountable.

The PLC splitter is the industry standard for modern PON networks due to its precision, scalability, and reliability. It is essential for FTTH deployments, 5G infrastructure, and data-intensive networks.

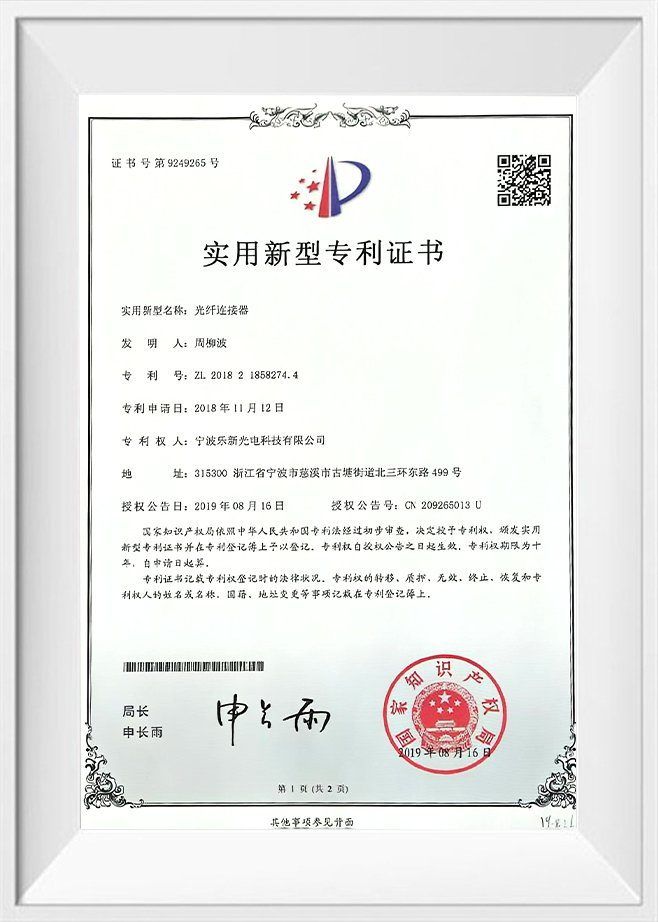

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom Fiber Optic PLC Splitter Supplier and OEM Fiber Optic PLC Splitter Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Jan 03, 2026_GoshiningIn modern fiber optic network cabling, the LC fiber optic fast connector has become a core component in FTTH (Fiber to the Home) and data center construction due to its small size, low loss, and ease of operation. It allows for cold splicin...Read More

-

Dec 26, 2025_GoshiningIn fiber optic communication networks, especially in the large-scale construction of FTTH (Fiber to the Home), SC Fiber Optic Fast connectors (Field Assembly Connectors) have become indispensable key components. With advantages such as no f...Read More

-

Dec 19, 2025_GoshiningIn modern optical communication networks, the Optical Distribution Frame (ODF) is an indispensable core component. Whether in large data centers, telecommunications equipment rooms, or enterprise LANs, the ODF plays the role of a "traffic h...Read More

As one of the core products of Ningbo Goshining Communication Technology Co., Ltd., the fiber optic PLC splitter (planar lightwave circuit splitter) is a passive optical device developed based on planar optical waveguide technology. It is used to evenly distribute a single input optical signal to multiple output ports. It is a key component in fiber-to-the-home (FTTH), passive optical network (PON) and multi-node optical signal distribution network. Relying on the company's integrated capabilities of designing, producing and selling a full range of optical fiber products, Ningbo Goshining is committed to providing customers with high-quality, high-reliability PLC splitters and one-stop optical communication solutions to meet the diverse needs from home access to backbone networks.

Working Principle

The PLC splitter uses semiconductor processes (such as photolithography and etching) to make micro-optical waveguide structures on quartz substrates. After the input optical signal enters the Y-type branch waveguide, the cascaded splitting structure is used to achieve 1xN or 2xN optical power distribution. The splitting principle is based on the mode coupling and energy distribution of the electromagnetic field in the waveguide. Ningbo Goshining's PLC splitter design optimizes the waveguide structure parameters to ensure the uniformity and low loss characteristics of optical signal diversion, providing stable optical signal distribution for FTTH, PON and other scenarios.

Core structure and packaging

1. Optical waveguide chip

As a core component, the waveguide chip uses high-purity silicon dioxide (SiO₂) or high-performance polymer materials, and realizes the optical signal splitting function through precise planar optical waveguide circuits. Ningbo Goshining strictly controls the purity of chip materials and the accuracy of waveguide structure to ensure the stability of optical performance and support flexible splitting ratio configuration from 1x2 to 2x64.

2. Fiber array

The input/output end uses a high-precision arranged single-mode fiber array (usually G.652.D fiber), which is seamlessly connected to the waveguide chip through 8-degree angle cutting and high-precision coupling technology. The company's self-developed coupling process ensures the alignment accuracy of the optical fiber and the waveguide, reduces insertion loss, and improves product consistency.

3. Packaging form

Ningbo Goshining provides a variety of packaging solutions to meet the needs of different scenarios:

Micro packaging (Micro): compact ABS box design, suitable for the inside of the optical distribution box;

Module/Plug-in packaging (Module/Plug-in): standard 1U rack module, easy to install on the ODF rack;

Tray packaging (Tray): adapted to fiber splicing tray or distribution box;

Stainless steel tube packaging (Blockless): high protection level design, suitable for harsh environments such as high temperature and high humidity.

All packages are filled with silicone or resin to enhance mechanical stability and environmental tolerance.

Key performance parameters

Ningbo Goshining's PLC splitter strictly follows industry standards in terms of performance and optimizes key parameters based on customer needs:

Split ratio: supports flexible configurations such as 1:4, 1:8, 1:16, 1:32, 1:64, 2x32, 2x64;

Working wavelength: covers single window (1310/1490/1550nm), dual window (1310/1490nm, etc.) and full band (1260-1650nm);

Insertion loss (IL): typical The value range is 3.6dB (1x2) to 21.0dB (1x64), which is better than the industry average;

Uniformity: The difference in insertion loss of each output port is ≤1.0dB, ensuring balanced signal distribution;

Return loss (RL): ≥55dB, reducing signal reflection interference;

Polarization dependent loss (PDL): ≤0.2dB, adapting to different polarization state inputs;

Environmental adaptability: operating temperature -40°C to +85°C, storage temperature in the same range, meeting industrial application requirements.

Main application scenarios

Relying on the advantages of a full range of fiber optic products, Ningbo Goshining's PLC splitters are widely used in the following scenarios:

FTTH network: distribute the trunk fiber optic signal to multiple user terminals (ONT/ONU) at the optical distribution point (ODP);

PON system: support optical signal branching of EPON, GPON, XG-PON, NG-PON2 and other technologies;

CATV optical network: realize multi-channel distribution of downstream broadcast signals;

Fiber optic sensing system: support multi-point signal collection and distribution;

Data center/enterprise network: adapt to LAN and building optical cable wiring needs.

In addition, the company provides customized services, which can adjust the splitting ratio, packaging form or integrate other fiber optic components (such as quick connectors, jumpers) according to customer's special needs to help create private brand products.

Key points of manufacturing process

Ningbo Goshining's PLC splitter production follows a strict quality control process:

Wafer deposition: growing a high-purity silica waveguide layer on a silicon substrate;

Photolithography and etching: forming a preset waveguide pattern through UV exposure and reactive ion etching (RIE);

Annealing treatment: optimizing the optical properties of the waveguide and reducing transmission loss;

End face grinding and polishing: ensuring the flatness and verticality of the waveguide end face and improving coupling efficiency;

Fiber array alignment coupling: using high-precision equipment to achieve precise alignment and permanent bonding of the optical fiber and waveguide end face;

Performance testing: comprehensive testing of key parameters such as insertion loss, uniformity, and return loss;

Packaging protection: assembling the shell and filling it with protective glue, and passing environmental reliability tests such as temperature cycling and vibration.

Selection considerations

Branch ratio: Determined according to the number of network users or branch nodes (such as 1x32, 2x64).

Working wavelength: Match the wavelength used by the system (single/dual/triple window).

Insertion loss: It needs to be included in the link power budget, and select products that meet the system margin requirements.

Packaging form: Select micro, plug-in, tray or stainless steel tube according to the installation environment (wiring box/rack/outdoor).

Operating Temperature: Choose between commercial or industrial temperature ranges depending on the deployment environment (indoor/outdoor).

Standards Compliance Confirm compliance with industry standards (e.g. IEC 61300-3, Telcordia GR-1209-CORE, GR-1221-CORE).