Everything You Need to Know About Fiber Optic Cables

2025-07-23

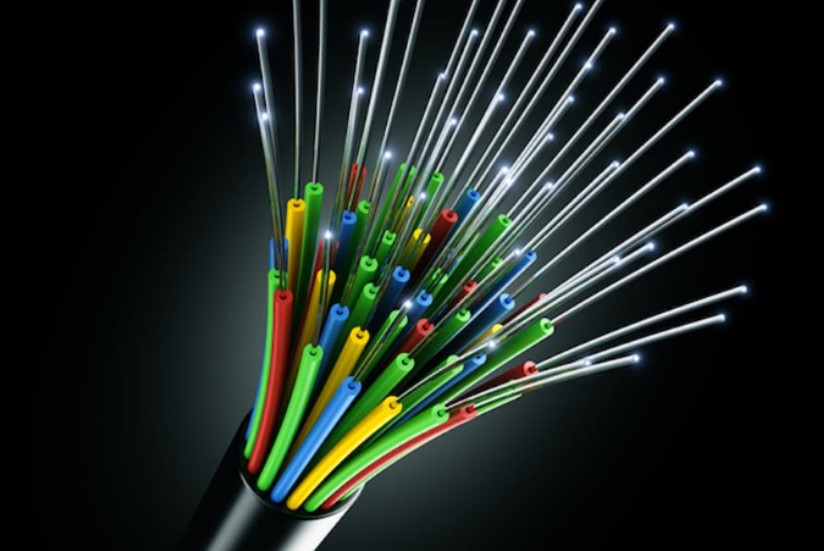

What Does Fiber Optic Cable Do?

Fiber optic cable is a communication medium that uses light waves to transmit information in optical fibers and is widely used in modern communication systems. It not only has significant technical advantages, but also shows great value in practical applications. The following will elaborate on the role of fiber optic cables from multiple aspects.

1. High-speed data transmission

One of the core advantages of fiber optic cables is its extremely high transmission rate. Compared with traditional copper cables, fiber optic cables use optical signals instead of electrical signals for data transmission, so they can achieve GHz-level bandwidth, far exceeding the limitations of copper cables. This means that a large amount of data can be transmitted simultaneously on fiber optic cables, such as high-bandwidth applications such as HD video, 4K/8K video streaming, virtual reality (VR), augmented reality (AR), etc.

In addition, the transmission speed of fiber optic cables is close to the speed of light (about 3×10⁸ m/s), making data transmission almost unaffected by delays, which is very suitable for application scenarios with extremely high real-time requirements, such as online games, telemedicine, financial transactions, etc.

2. Long-distance transmission

Another notable feature of fiber optic cables is their low loss characteristics. Since the propagation loss of optical signals in optical fibers is very low, they can be transmitted over longer distances without frequent signal amplification. This makes optical fiber cables very suitable for long-distance communications, such as cross-city and cross-country backbone network connections.

In contrast, copper cables can usually only be effectively transmitted within a range of tens of kilometers due to the rapid signal attenuation, while optical fibers can easily achieve transmission distances of hundreds of kilometers or even thousands of kilometers, greatly improving communication efficiency and network coverage.

3. Anti-electromagnetic interference

An important feature of optical fiber cables is their ability to resist electromagnetic interference. Since optical fibers themselves are made of glass and are non-conductive, they are not affected by electromagnetic fields like copper cables. This makes optical fiber cables more stable and reliable in strong electromagnetic interference environments (such as near high-voltage power facilities, industrial control environments, hospitals, etc.).

This feature is particularly important for communication systems that require high reliability (such as military communications, medical image transmission, industrial automation, etc.), ensuring the continuity and accuracy of data transmission.

4. High security

The physical properties of optical fiber cables also give them a natural advantage in information security. Since optical fiber is non-conductive and optical signals are not easily eavesdropped by external devices, optical fiber cables are more difficult to be illegally intercepted or monitored than copper cables. This makes optical fiber cables widely used in sensitive fields such as government, finance, and military to ensure the security of data transmission.

In addition, the signals of optical fiber cables are invisible, so even if someone tries to observe the inside of the optical fiber with the naked eye, they cannot obtain the transmission content, which further enhances its security.

5. Wide range of applications

The application range of optical fiber cables is very wide, covering almost all modern communications and information technology fields. Specifically including:

Telecom operator network: used to build a national or regional backbone network to provide high-speed Internet access.

Internet Service Provider (ISP): Provide fiber-to-the-home (FTTH) services for homes and businesses.

Cable television (CATV): Used to transmit high-definition video signals.

Data Center: Used to connect servers, switches and storage devices to achieve high-speed data exchange.

Medical industry: Used for remote diagnosis, surgical guidance and medical image transmission.

Industrial automation: Used for high-speed data transmission and control within the factory.

Military and defense: Used for confidential communications and command systems.

Transportation and Energy: Used for communication in smart grids, traffic monitoring, and energy management systems.

6. Support for multiple communication technologies

With the continuous development of communication technology, fiber optic cables have become an important infrastructure for the next generation of communication technologies (such as 5G, 6G, IoT, quantum communication, etc.). For example:

5G network: Although 5G mainly relies on wireless communication, its backhaul and fronthaul networks between base stations still use a lot of fiber optic cables.

Internet of Things (IoT): Fiber optic cables provide a guarantee for high-speed, low-latency communication between massive devices.

Quantum communication: Fiber optic cables are the basis for realizing quantum key distribution (QKD), laying the foundation for the development of future quantum Internet.

The flexibility and scalability of fiber optic cables enable them to adapt to the continuous evolution of future communication technologies.

7. Environmental protection and energy saving

Fiber optic cables also have certain environmental advantages during manufacturing and use. First, the raw materials of fiber optic cables are mainly quartz glass and plastic sheaths, and their production process has less impact on the environment than copper cables. Second, the low-loss characteristics of fiber optic cables mean that less energy is required during transmission, thereby reducing energy consumption and carbon emissions.

In addition, the longer life of fiber optic cables reduces the frequency of replacement, which also helps save resources and protect the environment in the long run.

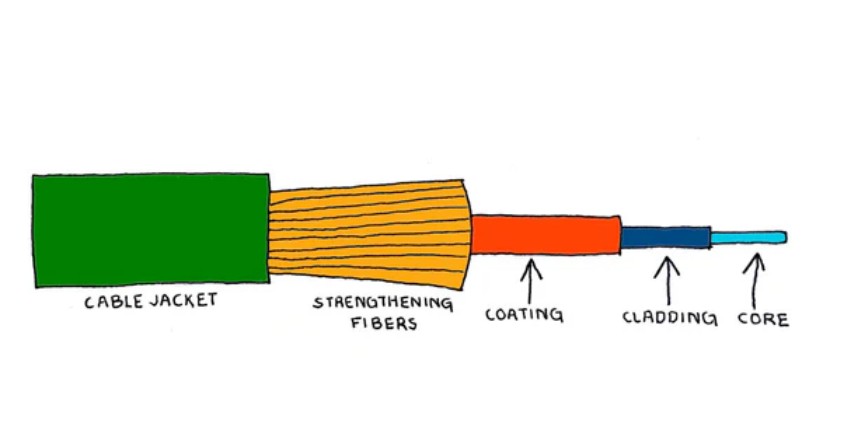

What parts does the structure of fiber optic cables include? How do these parts affect its performance?

The structure of fiber optic cables mainly includes the following parts: cable core, reinforcement elements and sheath. These parts each have different functions in fiber optic cables and have an important impact on the performance of fiber optic cables.

1. Cable core

The cable core is the core part of the fiber optic cable and consists of one or more optical fibers. The optical fiber itself consists of a core, a cladding and a coating.

Fiber core: It is the channel for light signal transmission, usually made of glass or plastic with a high refractive index. Its diameter determines the type of optical fiber (single mode or multimode). The core diameter of single-mode optical fiber is small (about 8.3 to 10 microns) and is suitable for long-distance transmission; the core of multimode optical fiber is larger (about 50 to 62.5 microns) and is suitable for short-distance high-bandwidth applications.

Cladding: Low refractive index material surrounding the core, used to confine the optical signal within the core through the principle of total internal reflection, ensuring efficient transmission of the optical signal.

Coating: Provides mechanical protection to prevent the core and cladding from being affected by external stress or wear.

The structural design of the cable core directly affects the transmission performance of the optical fiber. For example, the arrangement of optical fibers in the cable core (such as layer twisting, skeleton, bundle tube or ribbon) will affect the bending performance and lateral pressure resistance of the optical fiber.

2. Reinforcement elements

Reinforcement elements are used to enhance the mechanical strength of optical fiber cables so that they can withstand external forces such as tension and lateral pressure during installation and laying. Common reinforcement materials include steel wire, aramid yarn (Kevlar) and glass fiber reinforced plastic (FRP).

Central reinforcement element: Usually located in the center of the cable core to withstand tension.

Peripheral reinforcement element: Located near the sheath to enhance compression and bending resistance.

The selection and arrangement of reinforcement elements directly affect the mechanical properties of optical fiber cables. For example, in a strong electromagnetic interference environment, non-metallic reinforcement elements (such as aramid yarn) can avoid electromagnetic interference and improve the stability of signal transmission.

3. Sheath

The sheath is the outermost layer of the optical fiber cable, which is used to protect the internal structure from the external environment. The sheath is usually composed of an inner sheath and an outer sheath.

Inner sheath: Usually made of polyethylene (PE) or polyvinyl chloride (PVC), it is used to prevent moisture and provide preliminary mechanical protection.

Outer sheath: Different materials can be selected according to the laying environment. For example, the LAP outer sheath made of aluminum tape and polyethylene is suitable for direct burial laying, while steel wire armor is used in scenes that require higher pressure resistance.

The material and structural design of the sheath have an important influence on the corrosion resistance, temperature resistance, flame retardancy and UV resistance of the optical fiber cable. For example, some sheath materials have good flame retardant properties and are suitable for places with high fire protection requirements.

The influence of each part on the performance of optical fiber cable

Transmission performance: The structure and material of the cable core directly affect the transmission efficiency of the optical signal. For example, single-mode fiber has a smaller core and is suitable for long-distance transmission, while multimode fiber has a larger core and is suitable for short-distance high-bandwidth applications.

Mechanical properties: The design of the reinforcement elements and sheath determines the mechanical properties of the fiber optic cable, such as tensile strength, compression resistance, and bending resistance. For example, the choice of reinforcement elements will affect the applicability of the fiber optic cable in overhead, direct burial, or pipeline laying.

Environmental adaptability: The material and structure of the sheath determine the durability of the fiber optic cable in different environments. For example, some sheath materials have good corrosion resistance and UV resistance, which are suitable for outdoor or harsh environments.

Installation convenience: The structural design of the cable core (such as layer twisted type, skeleton type) and the arrangement of the reinforcement elements will affect the installation difficulty and flexibility of the fiber optic cable. For example, the layer twisted structure is easy to bend and wire, while the skeleton structure is more suitable for high-density wiring.

The structural design of the fiber optic cable is the key to its performance. The cable core, reinforcement elements, and sheath each have different functions and together determine the transmission performance, mechanical properties, and environmental adaptability of the fiber optic cable. By properly selecting and designing these parts, it is possible to ensure that optical fiber cables can achieve efficient and stable data transmission in various application scenarios.

How to choose a fiber optic cable for a specific environment? For example, which type should be used for overhead, underground or indoor installation?

Choosing a fiber optic cable for a specific environment needs to be determined based on the installation environment, application scenario and specific needs. The following are fiber optic cable selection recommendations for different installation environments (such as overhead, underground or indoor):

1. Overhead installation

Overhead installation is usually used outdoors, especially in scenarios where existing poles or towers need to be utilized. This installation method is suitable for long-distance communications between rural areas and cities, and scenarios that require a high installation position.

Recommended type: self-supporting optical cable (such as ADSS, OPGW).

Features:

ADSS (All-Dielectric Self-Supporting Cable): Non-metallic self-supporting optical cable, suitable for overhead installation, with good wind resistance, ice resistance and UV resistance.

OPGW (Optical Fiber Composite Ground Wire): Optical fiber composite overhead ground wire, usually used for power lines, with both power transmission and communication functions.

When choosing a fiber optic cable for a specific environment, it is necessary to make a reasonable configuration based on the actual application scenario and needs. For overhead installation, self-supporting optical cables (such as ADSS or OPGW) are recommended. The advantage is that they can make full use of existing power lines or communication tower resources without the need for additional supporting structures, thus saving construction costs and time.

Such optical cables have good wind, ice and UV resistance, and are suitable for long-distance, high-bandwidth communication needs, especially for rapid deployment in rural areas or between cities.

2. Underground installation

Underground installation is suitable for scenarios where concealed wiring is required, such as city centers, between buildings, or environments that need to avoid external interference. Underground installation methods include pipeline laying, direct burial and micro-trench construction.

Recommended types:

Pipeline laying: Use GYTS or GYTA type optical cables, suitable for pipe laying.

Direct burial laying: Use GYTA53 type optical cables, suitable for direct burial in the soil.

Micro-trench laying: Suitable for shallow underground installation to reduce the impact on the ground structure.

Features:

Armored optical cables: Such as GYTS, GYTA, etc., have a metal armor layer to provide additional mechanical protection.

Waterproof performance: underground optical cables usually have a waterproof design to prevent moisture penetration.

In underground installations, armored optical cables (such as GYTS, GYTA, etc.) have better physical protection capabilities and can effectively resist soil pressure, moisture erosion and external physical damage. They are suitable for scenarios that require high reliability and long-term stability to ensure the continuity and security of communication services.

3. Indoor installation

Indoor installation is suitable for wiring inside buildings, such as data centers, offices, homes, etc. Indoor optical cables usually do not need to withstand extreme environmental conditions, but need to meet safety requirements such as fire prevention and flame retardancy.

Recommended types:

Non-armored soft optical cables: such as GJYXFCH, GJXFH, etc., suitable for indoor vertical and horizontal wiring.

Spiral armored soft optical cables: such as GJYXFA-50, suitable for indoor environments that are anti-rat bite.

Features:

Good flexibility: easy to wire in narrow spaces.

Flame retardant design: meets indoor safety standards to prevent the spread of fire.

In indoor installation, non-armored or lightweight soft optical cables (such as GJYXFCH, GJXFH, etc.) are easy to install and suitable for rapid deployment. They are suitable for short-distance, high-density wiring needs, especially for office environments, data centers, and other scenarios that require high wiring efficiency and flexibility.

4. Choose the type of optical fiber

When choosing optical fiber cables, you also need to consider the type of optical fiber (single mode or multimode):

Single-mode fiber (SMF): Suitable for long-distance, high-bandwidth communications, such as FTTH, data center interconnection, etc.

Multimode fiber (MMF): Suitable for short-distance, medium-bandwidth requirements, such as local area networks, building internal wiring, etc.

5. Other considerations

Environmental factors: including temperature, humidity, ultraviolet radiation, chemical corrosion, etc., and optical cables with corresponding protection levels need to be selected.

Installation method: Different installation methods (such as overhead, pipeline, direct burial) will affect the selection of optical cables, and the appropriate structure needs to be selected according to actual conditions.

Cost and maintenance: Overhead installation has a lower cost, but maintenance is relatively complex; underground installation has a higher cost, but maintenance is more convenient.

What should be paid attention to when installing fiber optic cables?

The installation of fiber optic cables requires attention to multiple aspects to ensure their performance and safety. The following are detailed precautions:

Avoid excessive stretching and bending: The core of the fiber optic cable is made of glass and is relatively fragile, so during the installation process, avoid pulling the fiber itself directly, and only pull the parts with strength (such as aramid yarn or fiberglass rods). At the same time, avoid exceeding the minimum bending radius of the cable to avoid breaking the fiber.

Correctly handle the fiber end: Before installation, the fiber end should be processed with appropriate tools and techniques to ensure its smoothness and flatness to avoid signal loss caused by uneven ends.

Use appropriate lubricants: When installing optical cables in conduits, lubricants compatible with the protective jacket material of the optical cable should be used to reduce tensile loads and prevent damage to the optical fiber due to friction.

Avoid twisting and crossing: During installation, twisting and crossing of the fiber optic cable should be avoided, especially when rolling away from the spool, and twisting of the optical fiber should be avoided due to rotation.

Reserve margin: After the optical cable is laid, an appropriate margin should be left to prevent the optical cable from being too tight and to provide sufficient operating space when splicing is required.

Environmental conditions: The installation environment should meet the working requirements of the optical fiber equipment and avoid extreme temperature or humidity to avoid affecting the performance and life of the optical fiber.

Safety precautions: When installing optical cables in a large area, it is recommended to wear glasses with infrared filtering function to prevent direct viewing of the laser in the optical fiber from causing damage to the eyes.

Testing and acceptance: After the installation is completed, the optical cable length, loss, node connection and other tests should be carried out, using equipment such as optical cable testers and OTDR, and the results should be recorded and compared with the design requirements.

Marking and identification: Optical cables and their splices should have identification marks, and indicate the number, optical cable model and specifications, etc., for easy maintenance and management.

Professional operation: The installation of optical fiber cables should be carried out by experienced technicians to ensure correct operation and optimal performance.

By following these precautions, you can ensure the efficient and smooth operation of optical fiber cables, reduce maintenance costs, and extend their service life.

What is the service life and maintenance requirements of optical fiber cables?

The service life and maintenance requirements of fiber optic cables are key factors to ensure their long-term stable operation. The service life of fiber optic cables is generally between 20 and 30 years, or even longer, depending on the manufacturing quality, installation environment, and maintenance practices. In order to extend the service life of fiber optic cables, the following maintenance requirements and precautions need to be followed:

Avoid excessive stretching and bending: The core of the fiber optic cable is made of glass and is relatively fragile, so during the installation process, avoid pulling the fiber itself directly, and only pull the parts with strength (such as aramid yarn or glass fiber rods). At the same time, avoid exceeding the minimum bending radius of the cable to avoid breaking the fiber.

Properly handle the fiber end: Before installation, the fiber end should be processed with appropriate tools and techniques to ensure its smoothness and flatness to avoid signal loss caused by uneven ends.

Use appropriate lubricants: When installing optical cables in conduits, lubricants compatible with the protective jacket material of the optical cable should be used to reduce tensile loads and prevent damage to the optical fiber due to friction.

Avoid twisting and crossing: During installation, twisting and crossing of the fiber optic cable should be avoided, especially when rolling off the spool, and rotation should be avoided to cause twisting of the optical fiber.

Reserve margin: After the optical cable is laid, an appropriate margin should be left to prevent the optical cable from being too tight and to provide sufficient operating space when splicing is required.

Environmental conditions: The installation environment should meet the working requirements of the optical fiber equipment and avoid extreme temperature or humidity to avoid affecting the performance and life of the optical fiber.

Safety precautions: When installing optical cables over a large area, it is recommended to wear glasses with infrared filtering function to prevent direct viewing of the laser in the optical fiber from causing damage to the eyes.

Testing and acceptance: After the installation is completed, the optical cable length, loss, node connection and other tests should be carried out, using equipment such as optical cable testers and OTDR, and the results should be recorded and compared with the design requirements.

Marking and identification: Optical cables and their splices should have identification marks, and the numbers, optical cable models and specifications should be indicated for easy maintenance and management.

Operation by professionals: The installation of optical fiber cables should be carried out by experienced technicians to ensure correct operation and optimal performance.

By following these maintenance requirements, the efficient and smooth operation of optical fiber cables can be ensured, maintenance costs can be reduced, and the service life can be extended.