Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

FC Series Fiber Optic Fast connector Supplier

FC Series Fiber Optic Fast connector is a field-installable optical fiber connector that enables fast and easy optical fiber termination. It usually takes only a few minutes to install without complex tools or professional skills.

FC Series Fiber Optic Fast connector achieves precise alignment and connection of optical fibers through mechanical means, ensuring low insertion loss and high reliability.

FC Series Fiber Optic Fast connector supports multiple repeated installations, avoiding losses caused by excess optical fiber length or connector storage.

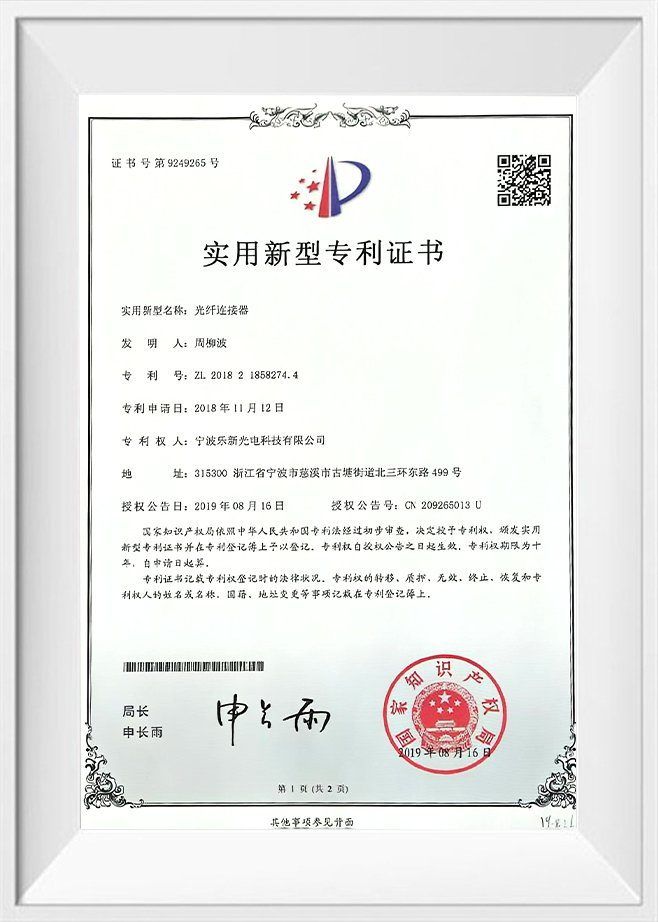

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom FC Series Fiber Optic Fast connector Supplier and OEM FC Series Fiber Optic Fast connector Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

1. What are the core concepts and basic components of the FC series fiber optic fast connector?

FC connector (Ferrule Connector) is a widely used fiber optic active connector, and its core component is a precision ceramic ferrule. The ferrule has a prefabricated microhole in the center for precise fixing of the bare fiber core.

The connector body usually adopts a metal thread structure, which is locked with the adapter by rotation, and has excellent mechanical stability and repeated plugging and unplugging performance.

The connector end face needs to be strictly polished (common PC/UPC/APC) to ensure that the optical signal has the lowest loss and the return reflection is minimized during docking. The APC end face has an 8-degree bevel design, which significantly reduces the return loss, especially for systems sensitive to reflection.

The core function is to achieve fast, low-loss, and highly reliable physical connection between two optical fibers or between an optical fiber and a device port, which constitutes an indispensable part of a complete optical channel.

2. What are the key performance indicators of FC connectors and the technical basis for achieving high-quality connections?

Insertion loss (IL) and return loss (RL) are the core indicators for measuring connector performance. High-quality FC connectors require an IL value lower than 0.3dB, and RL values usually require UPC>50dB, APC>60dB or even higher. This requires the concentricity of the ferrule, the radius of curvature of the end face, and the accuracy of fiber alignment to be controlled at the micron level.

The geometric tolerance, hardness and wear resistance of the precision ceramic ferrule (mainly made of zirconium oxide) are the core to ensure long-term stable connection. The inner diameter of the ferrule and the diameter of the fiber cladding must be highly matched to ensure that the fiber is accurately positioned in the hole.

The high-performance spring structure provides stable axial pressure to ensure that the connector is in close physical contact in the adapter. The strength, corrosion resistance and long-term mechanical stability of the shell material directly affect the reliability of the connector in various environments.

The precise control of the end face geometric parameters (radius of curvature, vertex offset, fiber height) and the ultra-smooth polishing process are the physical basis for achieving low insertion loss and ultra-high return loss.

3. What are the typical application scenarios and selection criteria of FC series connectors in optical fiber networks?

FC connectors are widely used in fixed connection points with high reliability requirements such as trunk optical cable lines, core equipment room equipment (such as OLT, transmission equipment, amplifiers), and test instrument ports due to their high strength and excellent vibration tolerance brought by their metal thread locking structure.

FC-APC type is the preferred connection interface for CATV optical nodes, analog RF transmission systems, and high-precision test environments due to its extremely low return loss characteristics, which can effectively suppress the interference of reflected signals on system performance.

In the fiber-to-the-home (FTTH) back-end wiring and the management of high-density optical fiber distribution frames (ODF/DDF) in data centers, FC connectors occupy an important position due to their reliability and mature installation and maintenance processes. When choosing, you need to comprehensively consider factors such as interface type (UPC/APC), application environment (indoor/outdoor), and expected number of plugging and unplugging times.

4. How does Ningbo Goshining Communication Technology Co., Ltd. ensure the high quality and reliability of its FC series optical fiber fast connectors?

Strict manufacturing standards drive stable performance: Ningbo Goshining Communication adheres to internal manufacturing standards that are higher than the general industry specifications, and runs through core processes such as precision ceramic ferrule selection, precision cutting, nano-level polishing, and three-dimensional interferometer full inspection. Each batch of products must pass strict insertion loss, return loss, interchangeability, repeatability, vibration, and environmental adaptability (temperature and humidity cycle) tests to ensure that the performance of factory products is stable and reliable, meeting or even exceeding international advanced standards such as Telcordia GR-326.

One-stop solution deeply integrates FC connector applications: As a professional optical communication component and solution provider, Ningbo Goshining Communication provides a complete value chain service around FC connectors. Starting from connector structure design and optical simulation optimization, it extends to mold development, precision injection molding/metal processing, automated assembly, full parameter testing, and finished product packaging and market supply, forming an efficient closed loop. This integration ensures the best adaptability and consistency of FC connectors in different application scenarios such as optical distribution frames, test jumpers, and equipment pigtails.

Customization supports diverse needs: Ningbo Goshining Communication has flexible customization capabilities to understand the uniqueness of different customers and application scenarios. According to the specific needs of customers, it can adjust the key specifications of FC connectors (such as specific loss target value, plug-in life level), adapt to special optical cable types or sheath materials, optimize packaging forms (single, bulk, reel), and provide exclusive brand logos (OEM/ODM) to ensure that the product is seamlessly integrated into the customer's system architecture and business processes.

5. In specific demand scenarios, what are the main aspects of the customization potential of FC series connectors?

Ningbo Goshining Communication can customize FC connector component materials for special application environments (such as high cold, high temperature, high humidity, and highly corrosive industrial scenarios), such as using special stainless steel shells and weather-resistant rubber seals to improve environmental tolerance.

According to the customer's on-site wiring density requirements, FC fiber jumpers of different lengths, different sheath materials (LSZH/PVX, etc.), and different tensile strengths can be customized to meet specific cabinet space or wiring path restrictions.

For high-end test instruments or special equipment port interfaces, we can provide FC connectors with ultra-low loss (such as IL<0.15dB) and ultra-high return loss (such as RL>65dB APC) to meet the most stringent performance index requirements.

We support customers to achieve in-depth customization in packaging, including but not limited to inner box design, reel size, label information (including traceability QR code), outer box logo, etc., to meet customers' supply chain management and brand image needs.