Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

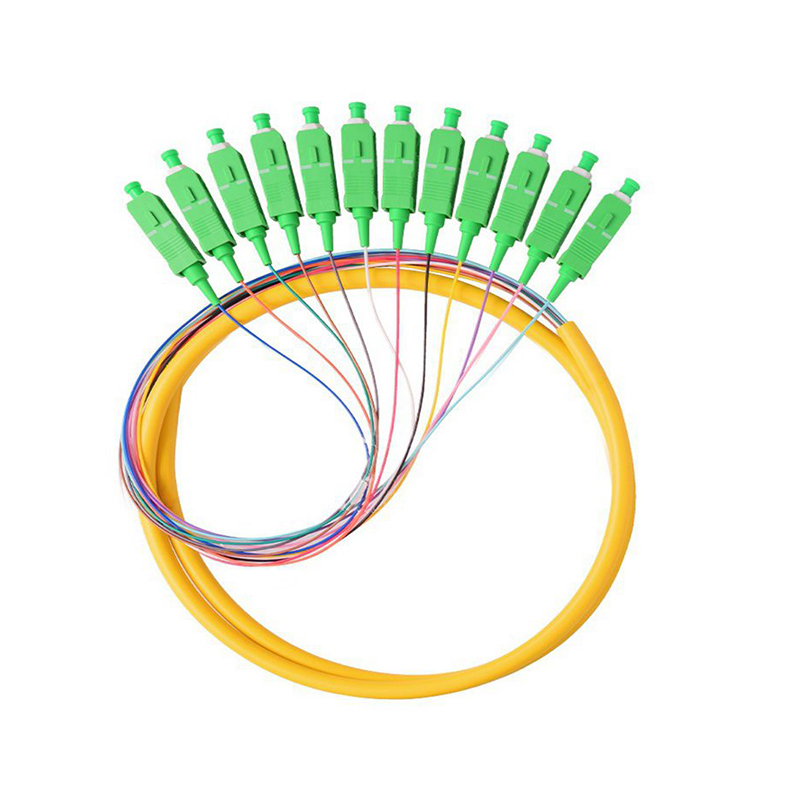

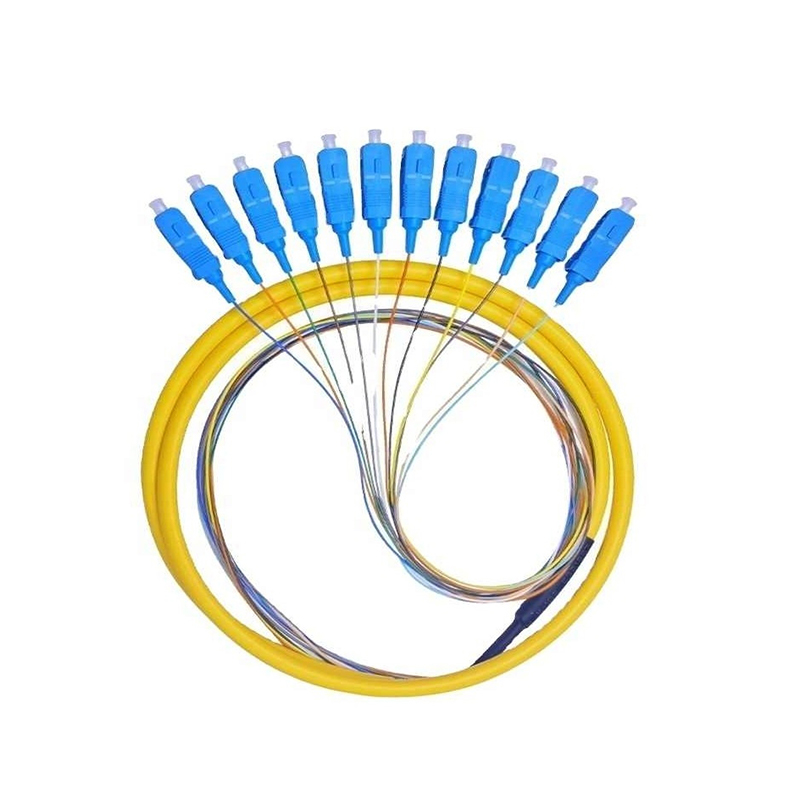

- SC series Fiber Optic Patch cord

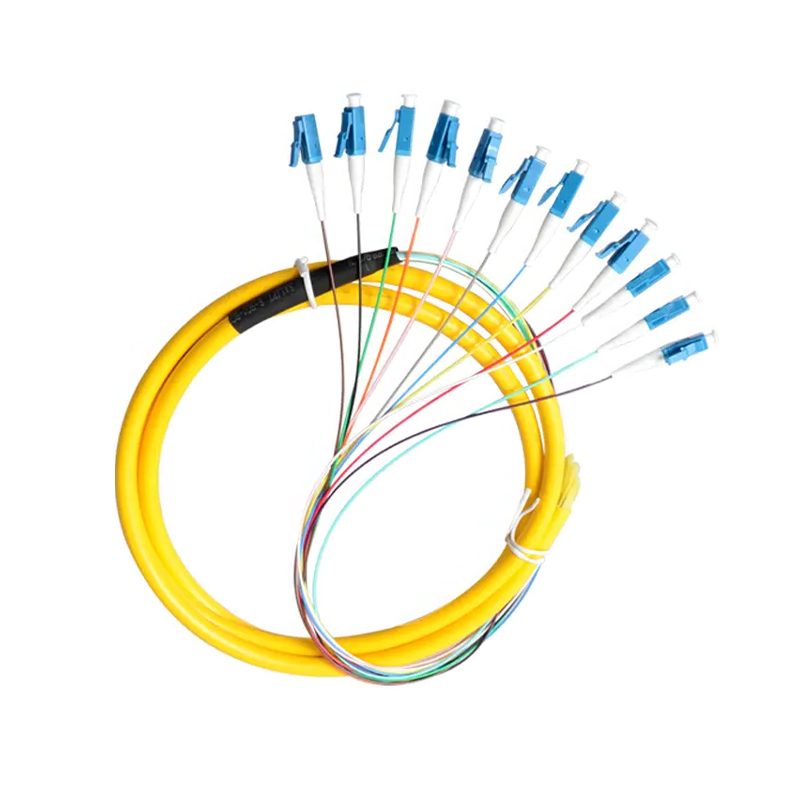

- LC Series Fiber Optic Patch cord

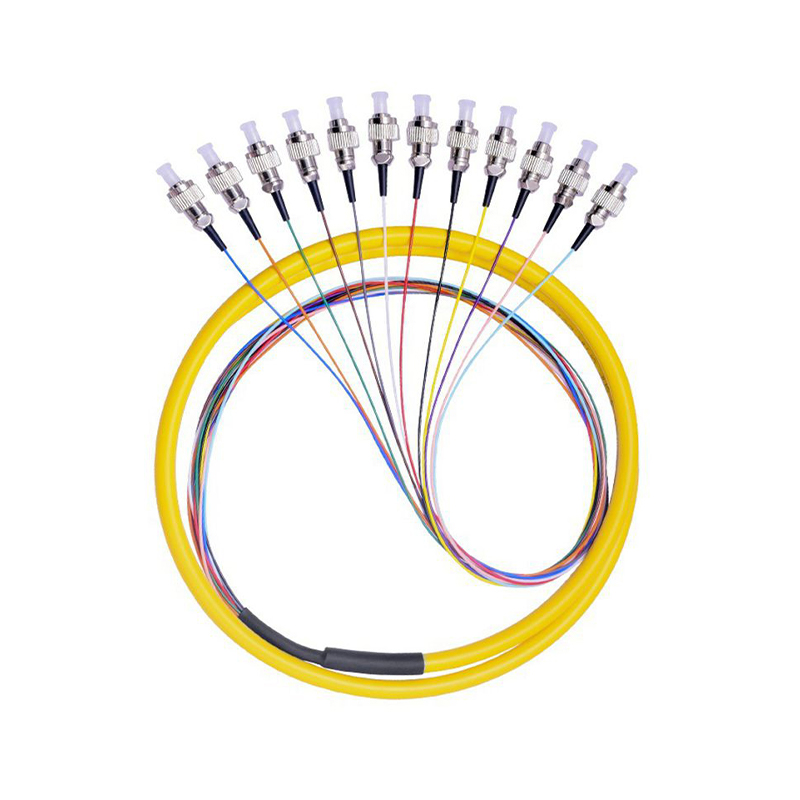

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

12 Multi Colors Fiber Optic Patch cord Supplier

Unlike standard fiber jumpers,12 Multi Colors Fiber Optic Patch Cord features a 12-color multi-strand design, allowing for easy identification and organization in high-density cabling environments.

Multi-Color Identification:The 12 distinct colors enable quick differentiation between multiple connections, reducing installation errors and simplifying maintenance in complex networks.

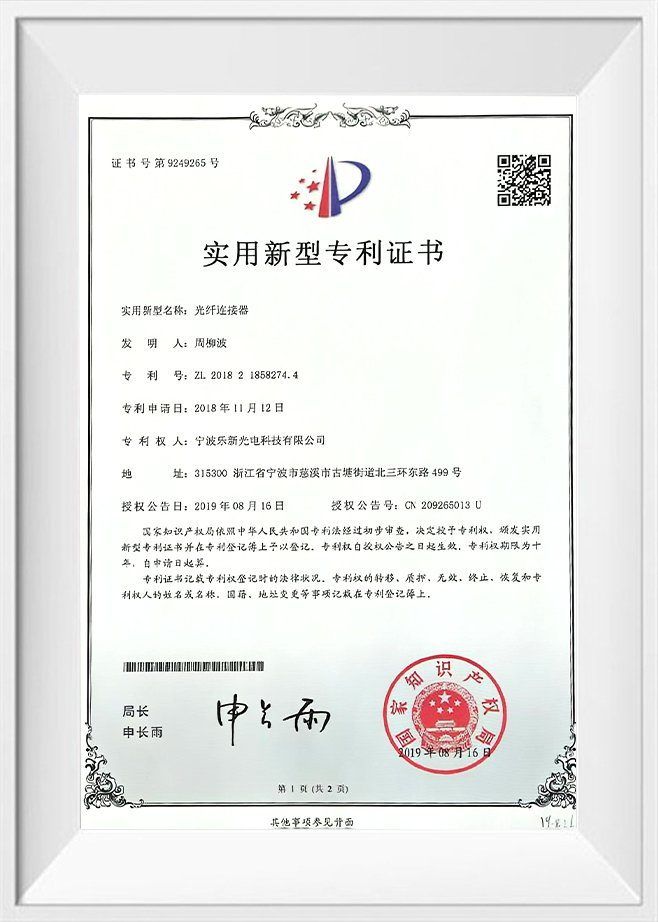

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom 12 Multi Colors Fiber Optic Patch cord Supplier and OEM 12 Multi Colors Fiber Optic Patch cord Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

12 Multi Colors Fiber Optic Patch cord: Smart solution for high-density cabling

In the increasingly complex optical network architecture, 12 Multi Colors Fiber Optic Patch Cord has become a core component for high-density connections. As a design that complies with the TIA-598-C international color standard, how does its unique 12 color spectrum system (blue/orange/green/brown/gray/white/red/black/yellow/purple/pink/light blue) improve operation and maintenance efficiency? Let's analyze key industry knowledge in depth.

1. The core value of color coding

Q: Why is strict adherence to the 12 color spectrum standard so important for data centers?

Fault location efficiency increased by 70%: Through accurate identification of fiber cores by color sequence, operation and maintenance personnel can locate faulty links within 3 seconds, significantly reducing MTTR (mean time to repair)

Compatible with global equipment ports: Compliant with IEC 60304 specifications, seamlessly connected to mainstream ODF patch panels such as Huawei/Cisco/Nokia

Anti-misinsertion design: Goshining uses ±0.1nm wavelength tolerance dyeing technology to ensure that it will not fade after 20 years of use and eliminate physical layer connection errors

II. Engineering advantages of 12-core configuration

Q: Compared with traditional single-core jumpers, how does the 12-core high-density solution save CAPEX?

Space utilization increased by 300%: a single jumper can achieve 12-way signal transmission, and 1U space supports 144-core wiring (traditional solutions only have 48 cores)

Bending radius optimized to 7.5mm: Goshining patented anti-bending layer design, passed IEC 61300-2-22 test standard

Insertion loss <0.2dB @1310nm: ultra-precision ceramic ferrule (ZrO₂ purity 99.99%) is used to ensure 40G/100G transmission stability

III. In-depth analysis of key application scenarios

Q: In which scenarios must OM3/OM4 level 12-core multimode jumpers be used?

Financial trading system: HFT high-frequency trading optical path with a delay requirement of ≤0.5ms

5G fronthaul network: 12×25Gbps parallel transmission under CPRI/eCPRI protocol

Modular data center: pre-terminated plug-and-play architecture (Goshining provides customized length + connector combination)

Ningbo Goshining core advantage embedding:

As a manufacturer certified by ISO 9001:2015 and GR-326-CORE, we use fully automatic concentricity calibration equipment to ensure that the radius of curvature (RPC) of the jumper end face is controlled in the optimal range of 5-15mm, and the plug-in life is greater than 1000 times. Support LC/SC/FC/MTP® full interface customization, 72-hour fast proofing and delivery.

IV. Professional purchasing guide

Q: How to verify the true performance parameters of 12-core jumper?

Certification requirements: Request an IEC 61300-3-34 test report issued by an independent laboratory (must include insertion loss/return loss/crosstalk matrix)

Structural verification: Confirm that the tensile strength is ≥120N (Goshining uses aramid reinforced core + LSZH flame retardant sheath)

Environmental adaptability: -40℃~+75℃ operating temperature range (passed UL 444 cold bending test)

Why 23 countries around the world choose Goshining?

→ One-stop optical communication solution: vertically integrated production capabilities from jumpers to splitters/distribution boxes

→ 48-hour emergency response mechanism: support air delivery of global emergency orders

→ ROHS 2.0 compliance guarantee: all materials comply with EU environmental directives