Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

Armored Series Fiber Optic Patch cord Supplier

Armored Fiber Optic Patch Cord is a fiber patch cord designed for harsh environments.

Easy to install and maintain: Armored fiber patch cords do not require additional protective sleeves, saving space and facilitating daily maintenance. Its design simplifies the installation process while reducing construction costs.

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom Armored Series Fiber Optic Patch cord Supplier and OEM Armored Series Fiber Optic Patch cord Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

Armored Series Fiber Optic Patch Cords: The Ultimate Solution for Industrial-Grade Communication Protection

Core Value: Why Choose Armored Patch Cords?

In harsh industrial environments, data centers, or outdoor deployments, how can you ensure that fiber optic patch cords are protected from physical damage, rodent bites, and accidental extrusion? The armored series provides 360° omnidirectional protection through a stainless steel braided layer, with a 300% increase in tensile strength while maintaining the precise transmission performance of 9/125μm single-mode or 50/125μm multi-mode optical fibers, completely solving the pain point of traditional patch cords being easily damaged.

Technical In-depth Analysis: The Scientific Logic of Armored Design

Question 1: Does the armor layer affect the bending radius and installation flexibility of the optical fiber?

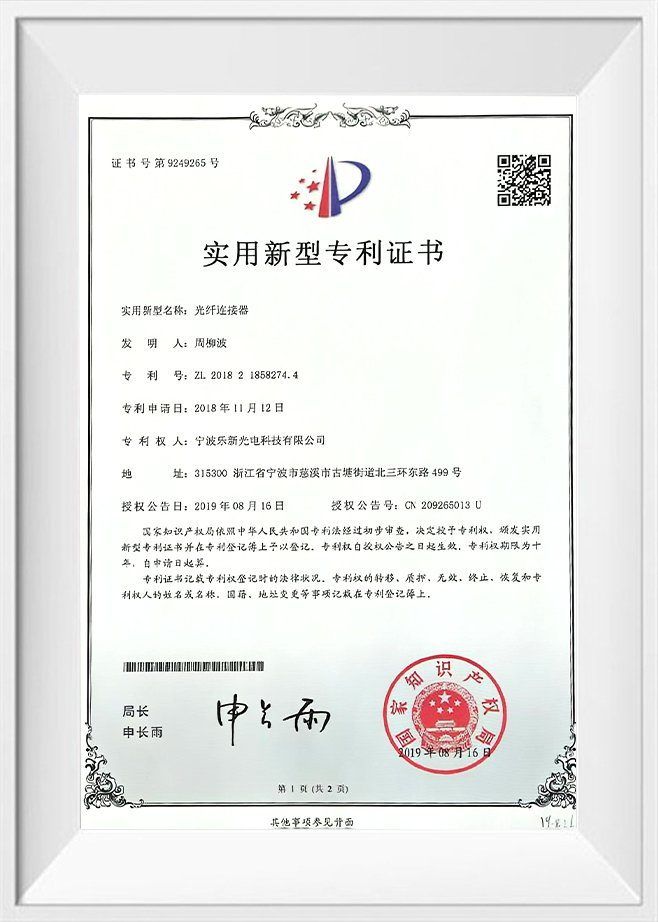

Ningbo Goshining's patented armored technology uses a micro-diameter stainless steel spiral structure with a minimum bending radius of ≤7.5mm (better than the industry standard of 10mm), which is compatible with high-density patch panel deployment. The outer LSZH (low smoke zero halogen) sheath simultaneously meets flame retardant and environmental protection requirements, and complies with ISO/IEC 11801 and TIA-568-D standards.

Question 2: How to ensure performance in extreme temperature and chemical corrosion scenarios?

With -40°C to +85°C wide temperature certification and IP67 protection level, the armor layer effectively isolates moisture, oil and acid-base corrosion, which is particularly suitable for harsh environments such as petrochemicals and smart transportation, significantly reducing failure rates and maintenance costs.

Goshining's differentiated advantage: Beyond standardized engineering capabilities

As a full-link optical communication product manufacturer, we provide:

✅ Customized armor solutions: support customized length (0.5m~100m), connector type (LC/SC/FC/MTP, etc.) and armor layer thickness on demand

✅ Zero additional loss guarantee: using ultra-precision grinding of ceramic ferrules (UPC/APC type), insertion loss ≤0.2dB, return loss ≥50dB

✅ One-stop delivery capability: from armored jumpers to matching splitters/distribution boxes, end-to-end system compatibility verification is achieved

Application scenarios: Who needs armored jumpers more?

Industry 4.0: Anti-electromagnetic interference wiring for factory automation equipment

5G infrastructure: High reliability interconnection between base stations

National defense security: Explosion-proof and anti-destruction communication network

Data center: Prevent accidental interruptions caused by rodents

Case study: The armored jumper solution provided by Goshining for a desert oil field in the Middle East has been running stably for 3 years under 50°C high temperature and sandstorm environment, with a failure rate of less than 0.1%.

Why choose Ningbo Goshining?

■ Vertical manufacturing system: From fiber drawing, connector injection molding to armor layer lamination, the whole process is autonomous and controllable

■ International certification matrix: RoHS/REACH/CE/GR-326-Core compliance, support third-party laboratory reports

■ 48-hour rapid response: The engineering team provides topology design support and failure analysis