Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

ST Series Fiber Optic Patch cord Supplier

The ST Series Fiber Optic Patch Cord is the ideal solution for professionals seeking a robust, high-performance optical interconnect with exceptional durability and ease of use.

Plug-and-Play Convenience: Pre-terminated connectors enable quick and tool-free installation, reducing deployment time and maintenance costs.

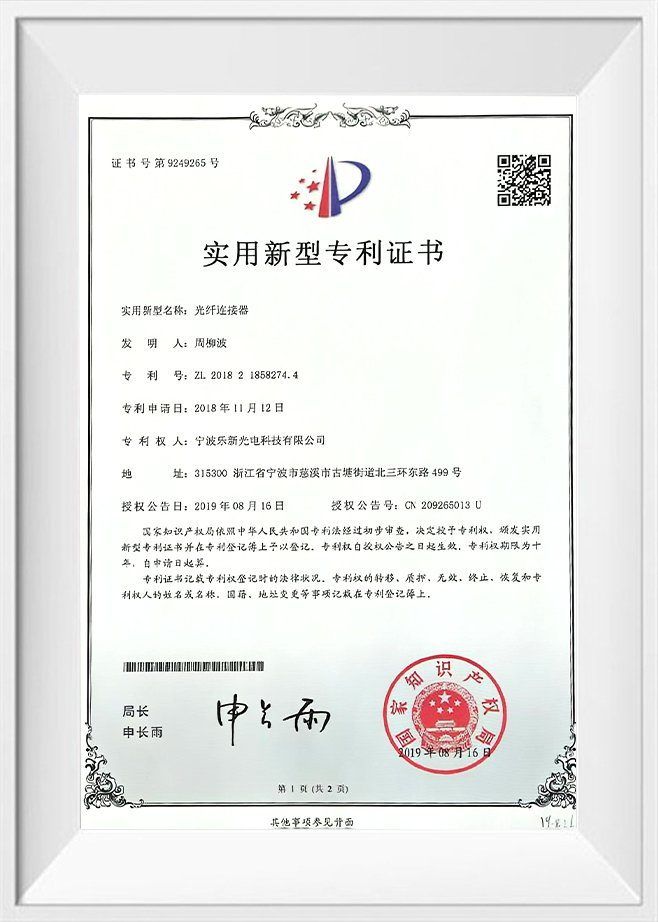

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom ST Series Fiber Optic Patch cord Supplier and OEM ST Series Fiber Optic Patch cord Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

ST Series Fiber Optic Patch Cord Industry Knowledge Analysis

1. Product Definition and Core Features

What are the main design goals of the ST Series Fiber Optic Patch Cord?

ST (Straight Tip) interface fiber optic patch cord is an early and widely used single-mode/multimode fiber connection solution. Its core design goal is to provide a physical connection with high stability and low insertion loss, which is suitable for scenarios such as data centers, local area networks (LANs) and telecommunications transmission.

Ningbo Goshining Communication's ST patch cord uses a ceramic sleeve (Ferrule) and high-precision polishing process to ensure that the end face flatness is ≤0.1μm, effectively reducing the return loss (RL≥50dB), and meeting the ITU-T G.652/G.657 standard.

Compared with SC/LC patch cords, what are the advantages and limitations of ST patch cords?

The ST interface uses a metal snap-on locking structure to achieve fast plugging and unplugging, which is suitable for frequent plugging and unplugging scenarios (such as test equipment), but its large size and plugging and unplugging require rotation operations, which limits its application in high-density wiring environments.

Ningbo Goshining Communication has significantly improved the plug-in life (≥500 times) by optimizing the clip spring tension (0.5-1.2N), and provides IP67 protection level options to adapt to harsh outdoor environments.

2. Application scenarios and technical adaptability

In which scenarios are ST jumpers still irreplaceable?

Although LC/MPO interfaces have gradually become mainstream, ST jumpers are still widely used in:

Traditional communication equipment upgrades: such as old switches and optical transceivers (compatible with equipment from Huawei, ZTE and other manufacturers);

Industrial automation control: The electromagnetic interference in factory workshops is strong, and ST's metal shell provides better shielding performance;

Medical endoscope system: High-definition images need to be transmitted through optical fiber, and ST's low loss characteristics ensure signal integrity.

Ningbo Goshining Communication has developed armored ST jumpers for industrial scenarios. The outer layer uses a stainless steel spiral sheath, which increases the crushing strength by 300% and extends the life to more than 10 years.

How to choose single-mode and multi-mode ST jumpers?

Single-mode (OS2): Suitable for long-distance transmission (≥10km), such as metropolitan area network backbone links;

Multi-mode (OM3/OM4): Supports short-distance high-speed transmission (≤550m@10Gbps), commonly used for interconnection within data center cabinets.

Ningbo Goshining Communication uses DMD (differential mode delay) testing to ensure the bandwidth of multi-mode jumpers. OM4 products support 40G/100G Ethernet and are compatible with IEEE 802.3ba standards.

3. Quality control and industry certification

What are the key quality indicators of fiber jumpers?

Insertion loss (IL): Ningbo Goshining Communication controls IL to ≤0.2dB (single-mode)/≤0.3dB (multi-mode) through 3D interferometer detection;

Return loss (RL): Adopting UPC/APC end face design, RL is ≥50dB/≥65dB respectively;

Environmental adaptability: Passing -40℃~+85℃ high and low temperature cycle test to ensure stable performance under extreme temperatures.

How does Ningbo Goshining Communication ensure product reliability?

The company has ISO 9001:2015 quality management system certification. All ST patch cords must undergo 100% end face inspection, 36-hour aging test and FiberChek fiber detector verification. In addition, the company supports customized services, such as non-standard length (0.5m-100m), special color identification (for easy wiring management) and customer LOGO printing.

4. Industry trends and competitive advantages

What is the future development direction of the fiber patch cord industry?

With the acceleration of 5G, data centers and FTTH (fiber to the home) construction, the industry presents two major trends:

Miniaturization: The proportion of LC/MPO interfaces has increased, but ST is still in demand in the stock market;

High density: Ningbo Goshining Communication launched a 1U 48-core ST patch panel, which increases space utilization by 40% compared with traditional solutions.

What are the core competitiveness of Ningbo Goshining Communication?

Integration of the entire industry chain: from optical fiber preform drawing to jumper assembly, achieving dual control of cost and quality;

Quick response capability: regular orders are delivered within 3 days, and urgent orders are processed within 24 hours;

Global service network: products are exported to more than 30 countries including Europe, America, Southeast Asia, etc., providing multi-language technical support.