Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

Rack-Mountable Fiber Optic PLC Splitter Supplier

Rack-Mountable Fiber Optic PLC Splitter devices are usually equipped with pre-installed routing guides and quick removal functions for easy on-site installation and maintenance. In addition, its modular design makes fiber management and connection more convenient.

Rack-Mountable is compatible with a variety of PON technologies such as EPON, GPON, BPON and XGS-PON, and can meet bandwidth requirements from Gigabit to 10Gbps and even higher.

Due to its passive design, Rack-Mountable does not require an external power supply, reducing operating costs and improving the energy efficiency of the network. Its high cost-effectiveness makes it an ideal choice for FTTH network deployment.

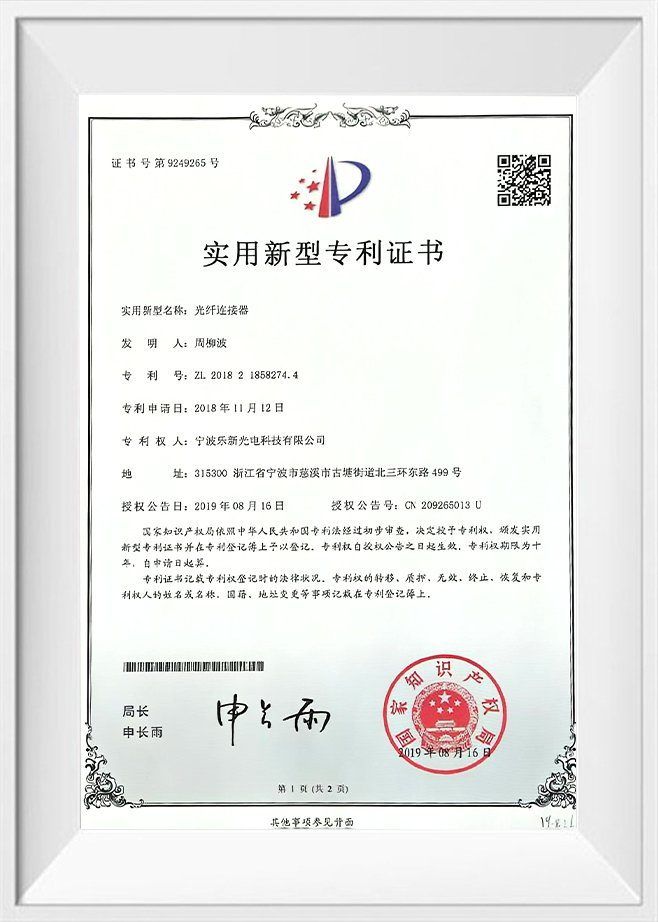

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom Rack-Mountable Fiber Optic PLC Splitter Supplier and OEM Rack-Mountable Fiber Optic PLC Splitter Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

The rack-mounted fiber optic PLC (planar optical waveguide) splitter is a passive optical device installed in a standard 19-inch communication rack. Its core function is to split a single input optical signal to multiple output ports (such as 1x4, 1x8, 1x16, 1x32, 1x64). Its core is based on optical waveguide circuits on a quartz substrate to achieve splitting, with the characteristics of precise splitting ratio, wavelength insensitivity (1260-1650nm), and low polarization-related loss.

1. Physical structure and characteristics

Housing: A metal shell with a standard 19-inch rack width (usually 1U or 2U height) with good heat dissipation and electromagnetic shielding.

Modular design: Usually contains multiple independent PLC splitter modules (such as plug-in card or tray type), supporting flexible configuration and expansion.

Port: The input/output ports are standard fiber optic adapters (such as SC/UPC, LC/UPC) located on the front of the panel for easy operation. The port configuration is clearly marked (such as: IN, OUT1-OUTn).

Pigtail type: Internal connections usually use bend-resistant single-mode fiber (such as G.657.A1/A2).

Installation: Provide rack mounting ears that comply with the EIA-310-D standard and are fixed to a 19-inch communication cabinet/rack with screws.

Goshining Advantage: Customizable port configurations and split ratios to align with your network topology.

2. Key optical performance parameters

Split ratio: A clear split ratio (such as 1:4, 1:32).

Operating wavelength: Usually supports the range of 1260nm to 1650nm, covering the main communication windows of single-mode fiber (O/E/S/C/L bands).

Insertion loss: The inherent attenuation of the signal passing through the splitter. The typical value increases with the increase of the split ratio (for example: 1x8 is about 10.5dB ± 0.8dB).

Uniformity: The maximum difference in insertion loss between each output port (typical value: ≤1.0dB).

Polarization-dependent loss: The loss change caused by the change in the polarization state of the input light (typical value: ≤0.2dB).

Directivity: Isolation between input port and output port (typical value: ≥55dB).

Return loss: Ratio of reflected optical power at input port to incident optical power (typical value for UPC interface: ≥50dB).

Operating temperature range: Typically -40°C to +85°C (or -5°C to +70°C).

Storage temperature range: Typically -40°C to +85°C.

Goshining Quality: Rigorous testing ensures industry-leading consistency and longevity.

3. Main advantages

High-density integration: Integrate a large number of branch ports in a limited rack space to optimize space utilization.

Centralized management: Facilitates unified wiring, maintenance and management in a central machine room, optical distribution frame (ODF) or base station.

High reliability: PLC chip technology is mature, the structure is stable, there are no moving parts, and the service life is long.

Environmental adaptability: The sturdy casing provides good physical protection and temperature stability.

Good consistency: PLC technology ensures that the loss and wavelength response of each channel are highly consistent.

Wide working bandwidth: Supports current and future mainstream single-mode fiber communication wavelengths.

4. Typical application scenarios

Fiber to the home (FTTH/PON network): Realize signal distribution from a single feeder fiber to multiple users (ONU) at the central office (OLT side) or optical distribution point (optical branching point in ODN) (commonly used 1310/1490/1550nm).

Cable TV (CATV) optical transmission: Distribute downlink broadcast signals at optical nodes (commonly used 1550nm).

Fiber optic local area network (LAN) and data center: Used for signal distribution of backbone optical fibers.

Distributed antenna system (DAS): Distribute optically carried RF signals to multiple antennas.

Testing and monitoring: Distribute signals to multiple test equipment or monitoring points at the same time.

5. Installation and deployment considerations

Cabinet space and heat dissipation: Plan sufficient rack space (U position) and ensure that the cabinet is well ventilated.

Fiber management: Use tools such as cable management rings and fiber optic troughs to lay out input/output pigtails in an orderly manner to avoid excessive bending (bending radius ≥ 30mm) and extrusion to prevent additional loss or damage. Reserve an appropriate length of fiber for maintenance operations.

Port cleaning: Before installing the connection, use professional fiber optic cleaning tools to clean the fiber optic connector end face and the inside of the splitter adapter to avoid dust pollution that causes increased loss or connection failure.

Connection operation: Align the adapter type (such as SC/LC) and the end face type (such as UPC/APC) to ensure that the plug is fully inserted into the adapter and locked in place.

Label identification: Clearly mark the corresponding relationship and purpose of the input and output ports to facilitate future maintenance and troubleshooting.

Test verification: After installation, use an optical power meter and a stable light source to perform an end-to-end link loss test to verify whether the splitter performance and the overall link meet the standards.

6. Relevant standards and certifications

The design, production and testing of rack-mounted PLC splitters usually follow international and industry standards, including but not limited to:

Telcordia GR-1209-CORE / GR-1221-CORE

IEC 61300-3 (series of standards)

IEC 61753-1 & IEC 61753-021-2 / 021-3

TIA/EIA-455-B (FOTP series)

ITU-T G.671

RoHS (Restriction of Hazardous Substances Directive)