Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

Fiber Optic ODF Manufacturer

Optical Distribution Frame (ODF) is a standardized rack or cabinet used in fiber optic communication networks to organize, terminate, splice, and distribute optical fibers. It serves as a central hub for managing fiber connections between incoming/outgoing cables, patch cords, and network equipment.

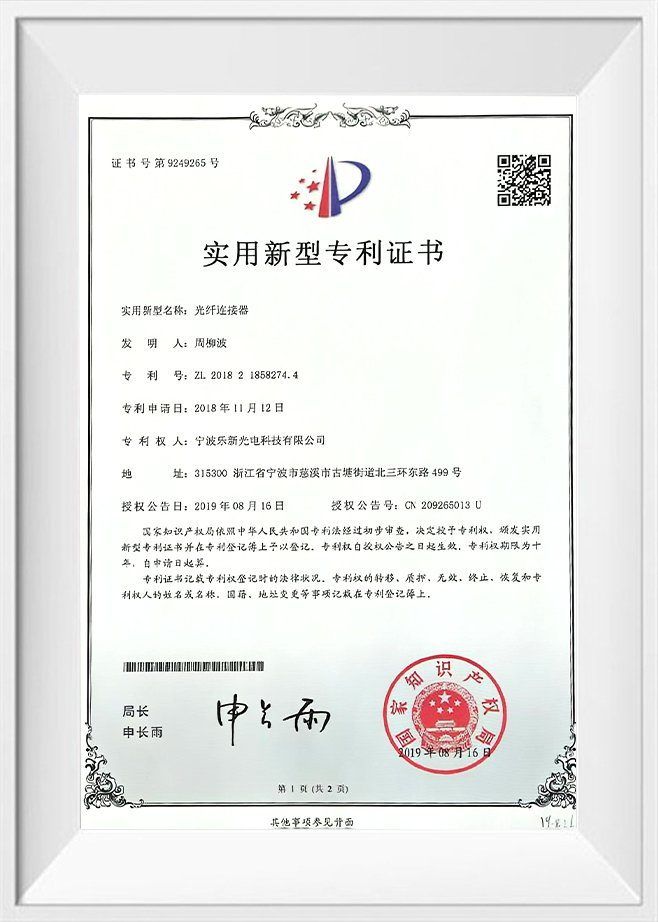

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Wholesale Fiber Optic ODF Manufacturer and OEM ODF Fiber Optic Distribution Frame Supplier, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

Fiber optic patch panels are core equipment for fiber optic connection, distribution and management in fiber optic communication systems. Their main functions are reflected in the following aspects:

First, fiber optic patch panels realize the orderly connection of fiber optic lines. In communication networks, a large number of optical fibers need to be connected to each other, and fiber optic patch panels provide a standardized platform to make these connections orderly. It can centrally manage optical fibers from different directions, avoid line confusion, and greatly improve the maintainability of the system.

Second, fiber optic patch panels provide reliable protection functions. The fiber core is extremely fragile and susceptible to physical damage and environmental factors. Through its sturdy shell and internal structure, the patch panel provides mechanical protection and environmental isolation for key parts such as fiber optic connectors and fusion points, effectively preventing erosion by external factors such as dust and moisture.

Fiber optic patch panels facilitate flexible deployment of lines. As business needs change, fiber optic lines may need to be adjusted frequently. The design of the patch panel enables technicians to quickly and conveniently perform fiber jumper, testing and maintenance operations, greatly improving work efficiency.

Finally, fiber optic patch panels help achieve standardized management. Through a unified interface and identification system, the patch panel makes the complex fiber optic network visual and standardized, which is convenient for daily management and troubleshooting.

The working principle of the fiber optic patch panel is based on the basic principle of fiber optic communication and combines the concept of structured cabling. Its core function is to realize the distribution and transfer of optical signals without processing or changing the signal itself. When the optical signal is transmitted to the patch panel through the optical fiber, it first enters the incoming line area of the patch panel. Here, the optical fiber is usually fixed on an appropriate support structure and necessary coiling is performed to maintain an appropriate bending radius to avoid optical signal attenuation caused by excessive bending.

Subsequently, the optical fiber can be connected in the patch panel in two main ways: one is direct docking with optical fiber connectors, and the other is to achieve permanent connection through fusion. The connector docking method is flexible and easy to adjust later; the fusion method has lower loss and higher stability. There are usually special fusion trays or adapter panels inside the patch panel to support these two connection methods.

After the connection is completed, the optical signal can be distributed to different outlet ports through jumpers or pigtails, and then connected to the corresponding communication equipment or other optical fiber lines. During the entire process, the distribution frame ensures that the optical fiber is routed reasonably, the bends are appropriate, and all connection points are firm and reliable, minimizing signal loss.