Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

Waterproof box Supplier

Waterproof box uses factory-prefabricated optical fiber components, which do not require on-site splicing. Connections can be completed by inserting adapters, which significantly shorten construction time, support parallel construction, and greatly improve construction efficiency.

Waterproof box reduces construction costs by reducing on-site splicing and labor costs. At the same time, the use of prefabricated components reduces material waste and further optimizes the cost structure.

Waterproof box supports visual management of ODN resources, and realizes automatic collection and management of optical fiber link information through QR codes or RFID tags, improving operation and maintenance efficiency.

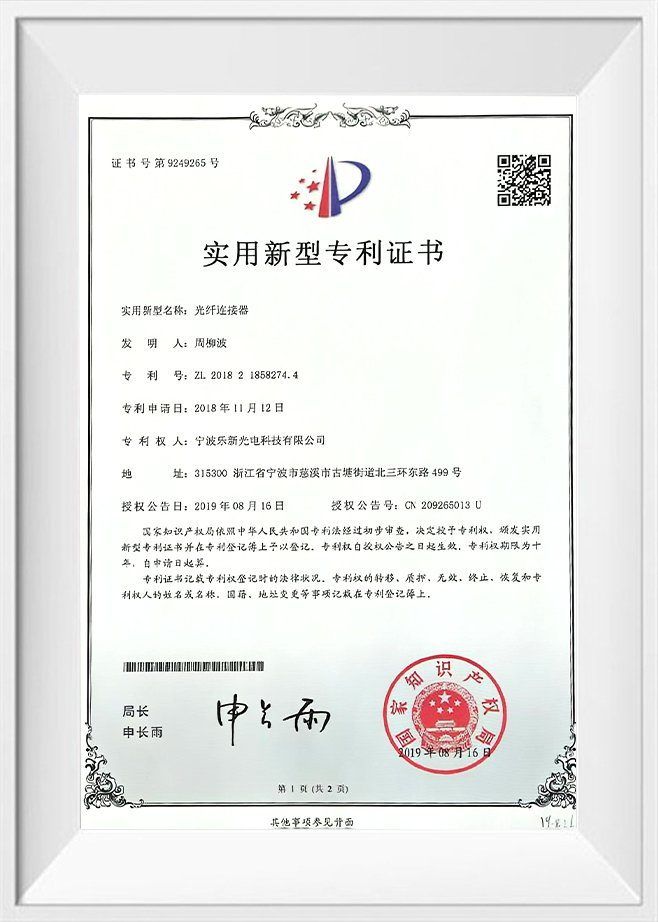

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom Waterproof box Supplier and OEM Waterproof box Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

Q1: What is the basic concept of waterproof box? Why does it play a key role in the field of electronic protection?

Definition and core functions of waterproof box: A waterproof box is a protective shell specially designed to isolate moisture, dust and other environmental factors; it prevents liquid from invading internal electronic components through a sealed structure to ensure stable operation of the equipment in a humid or dusty environment; this type of shell is widely used in communication equipment, outdoor monitoring systems and industrial automation to ensure the reliability of signal transmission and the long-term life of the equipment.

Important position in electronic protection: The waterproof box is not just a simple container accessory, but the cornerstone of modern communication infrastructure; it can effectively reduce the failure rate of equipment and extend its service life, thereby reducing maintenance costs and improving overall system efficiency; in high-risk environments, such as coastal areas or under changeable weather conditions, its protective performance is directly related to the continuity and security of critical data.

Ningbo Goshining Communication Technology Co., Ltd.'s combination point: As a professional enterprise focusing on communication solutions, the company deeply understands the urgent needs of users for equipment protection; through strict factory management processes, it ensures that each waterproof box fits the actual application scenario; for example, in the construction of 5G base stations, the waterproof boxes provided by the company can not only meet the IP68 top waterproof standards, but also customize the size and sealing solutions according to user feedback; this is due to Ningbo Goshining Communication Technology Co., Ltd.'s consistent quality-oriented concept, which regards the waterproof box as one of the core components to ensure the stability of the customer's communication system.

Q2: How does the working principle and sealing mechanism of the waterproof box achieve efficient protection?

Overview of the core working principle: The protectiveness of the waterproof box comes from the multi-layer sealing design; including rubber gaskets, precision injection molding edges and snap-on closure systems; these components work together to form a physical barrier to prevent water molecules from penetrating; at the same time, the internal pressure balance design avoids condensation problems caused by temperature differences, ensuring that the internal dry environment can still be maintained in heavy rain or high humidity environments.

Key sealing technology details: In terms of material selection, silicone or EPDM rubber sealing rings are commonly used, whose elasticity and weather resistance can withstand extreme temperature changes; in terms of structure, the box body adopts an integrated injection molding process to reduce joint weaknesses; the entrance hole is equipped with a waterproof connector, such as the MIL-C-26482 specification, to ensure the absolute sealing of the cable access point; the test process includes water pressure and vacuum testing to verify its protection ability when immersed in 1 meter of water for more than 30 minutes.

Ningbo Goshining Communication Technology Co., Ltd.'s combination point: The company optimizes the sealing process of waterproof boxes with a meticulous attitude; through continuous improvement of production lines, such as the introduction of automated testing equipment, ensure that each box body undergoes strict water tightness testing before leaving the factory; this strict factory management reflects Ningbo Goshining Communication Technology Co., Ltd.'s quality commitment-not only meeting the IP protection level requirements, but also developing an anti-loosening locking mechanism for the high-frequency vibration environment of communication equipment; thus making the waterproof box a reliable guarantee trusted by customers.

Q3: What are the key considerations for material selection and design requirements of waterproof boxes?

Mainstream material types and their advantages and disadvantages: Waterproof boxes often use engineering plastics such as polycarbonate (PC) or ABS resin; PC materials provide high strength and UV resistance, suitable for long-term outdoor exposure scenes; metal alloys such as aluminum alloys are used for heavy industrial applications, with excellent impact resistance, but require additional anti-corrosion coatings; material selection needs to weigh cost, weight and environmental adaptability, for example, stainless steel reinforced versions are preferred in corrosive environments.

Design elements and innovation trends: In terms of design, modularity and compatibility are emphasized; for example, embedded rails facilitate the installation of circuit boards, and ventilation valves are designed to balance internal and external air pressure; innovation directions include lightweight thin-walled structures and environmentally friendly recyclable materials; the protection level is based on international IP standards (such as IP67/IP68), which define the applicable boundaries of waterproof boxes; at the same time, the box shape is optimized to reduce dead corners of water accumulation and improve overall durability.

Ningbo Goshining Communication Technology Co., Ltd.'s combination point: Driven by strong learning ability, the company continues to explore material innovation; for example, in response to the salt spray corrosion problem of coastal communication towers, a nano-coated PC waterproof box was developed to extend the service life by more than 20%; Ningbo Goshining Communication Technology Co., Ltd. has strong innovation capabilities, which are reflected in customized design services-according to customer-specific needs, such as miniaturized IoT device protection, ultra-thin high-sealing solutions are provided; this user-centric research and development ensures that waterproof boxes not only meet industry specifications, but also promote the evolution of protection technology.

Q4: How are the common application scenarios and industry standards of waterproof boxes classified?

Analysis of wide application areas: Waterproof boxes are ubiquitous in communication base stations, traffic signal systems, energy monitoring sites and smart home devices; for example, in outdoor fiber optic terminal boxes, it isolates rainwater to ensure zero signal interruption; in industrial automation scenarios, it protects robot control units from dust; application classification includes fixed installation boxes, portable protection boxes and embedded module housings, each designed for specific environmental risks.

Industry standards and performance classification: International standards such as IEC 60529 define the IP protection grade system; IP67 represents protection against short-term immersion, and IP68 ensures long-term underwater protection; in addition, the NEMA 4X standard covers corrosion and hail resistance; the actual selection needs to be combined with environmental factors, such as temperature range (-40°C to 85°C) and chemical exposure; performance verification is verified by third-party certification to ensure the versatility of waterproof boxes in different climates around the world.

Ningbo Goshining Communication Technology Co., Ltd.'s combination point: The company is guided by meeting user needs and deeply cultivates communication industry applications; for example, it provides mobile network operators with IP68 certified waterproof boxes to adapt to the high-density deployment of 5G micro base stations; through continuous improvement, Ningbo Goshining Communication Technology Co., Ltd. has accumulated a large amount of scene data and optimized the classification strategy of waterproof boxes - from urban rooftops to remote mountainous areas, ensuring that each product achieves customer-satisfactory protection effects; this data-driven service strengthens the company's professional position in the field of communication protection.

Q5: What are some practical suggestions for the maintenance, care and optimization selection strategy of waterproof boxes?

Key steps for maintenance: Regularly check the aging of the seal ring, and the replacement cycle is recommended every 2-3 years; Use neutral solvents when cleaning to avoid corrosion; Test the closing pressure after installation to ensure uniform force; Keep storage conditions in a dry environment to prevent ultraviolet rays from accelerating material degradation; These measures can significantly extend the service life of the waterproof box and reduce unexpected failures.

Key points of optimization selection strategy: Evaluate the environmental risk level when purchasing - for example, IP68 products are preferred in high-humidity areas; Size matching equipment reserves space to avoid excessive squeezing of cables; Brand selection focuses on factory traceability, such as Ningbo Goshining Communication Technology Co., Ltd.'s full-process traceability system; Cost-benefit analysis should not sacrifice quality. Although the top protection has a high initial investment, it can reduce long-term maintenance expenses.

Ningbo Goshining Communication Technology Co., Ltd.'s combination point: The company focuses on customer satisfaction and provides all-round support; for example, through strict factory management, the factory waterproof box comes with a maintenance guide and spare parts package; Ningbo Goshining Communication Technology Co., Ltd. has a strong learning ability and iterates products from feedback - such as developing an easy-to-disassemble design to simplify the maintenance process; This reflects the culture of continuous improvement, making the waterproof box not only a protective tool, but also a partner to improve user operational efficiency. Ultimately, Ningbo Goshining Communication Technology Co., Ltd.'s professional accumulation in the field of waterproof boxes stems from its strong innovation capabilities and unremitting pursuit of quality, injecting reliable protection power into global communication equipment.