Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

Waterproof connector Supplier

By reducing the need for professional technicians and reducing construction complexity, Waterproof connector reduces labor costs and overall deployment costs.

Waterproof connector supports flexible network expansion and can adapt to the FTTH deployment needs of different scales. Through prefabricated fiber distribution boxes and optical cable components, the network structure can be dynamically adjusted according to user density.

Waterproof connector supports modular design and can be plug-and-play without complex on-site operations.

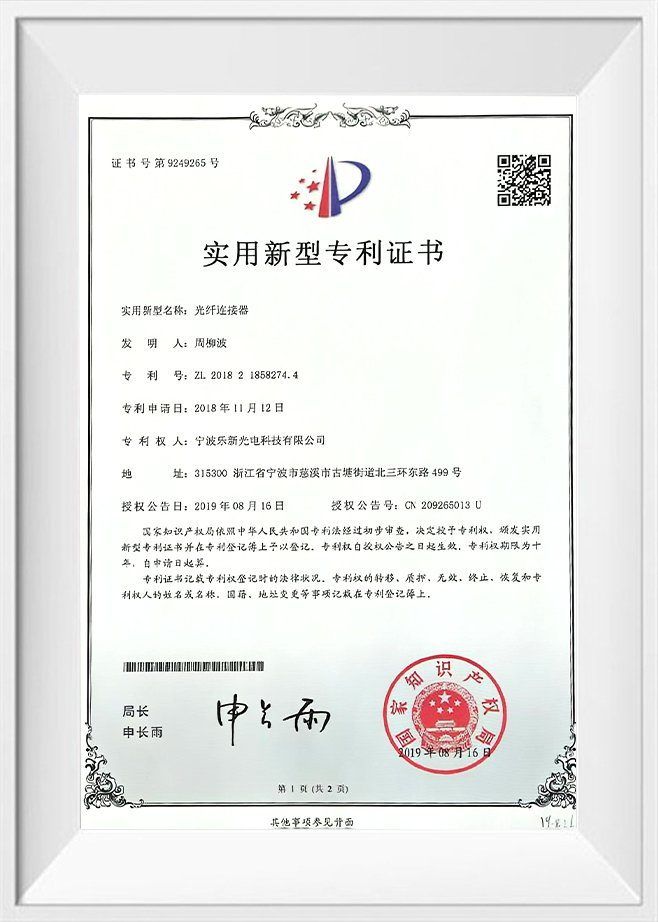

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom Waterproof connector Supplier and OEM Waterproof connector Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

Question 1: What is the working principle of waterproof connectors and why is it necessary?

Answer:

Waterproof connectors achieve environmental protection through sealing structure and material selection, preventing moisture or dust from invading the internal circuit, ensuring the stability and safety of electrical connections.

Its necessity stems from the application requirements in harsh environments, such as outdoor equipment or humid areas, to prevent short circuits, corrosion and equipment failure, thereby extending product life and reducing maintenance costs.

Ningbo Goshining Communication Technology Co., Ltd. uses advanced production equipment, such as precision injection molding machines and automated testing systems, to ensure that the sealing performance of connectors reaches the industry-leading level, while optimizing material selection by introducing international manufacturing technology to improve overall reliability.

Question 2: What are the key features of waterproof connectors?

Answer:

The core features are reflected in the sealing level, which usually adopts the IP (Ingress Protection) standard, such as IP67 or IP68, indicating that it can work normally at a certain depth underwater or in a high-pressure environment.

Material selection is crucial, including waterproof silicone, corrosion-resistant metals and UV-resistant plastics, which maintain elasticity and insulation under conditions such as high and low temperatures and chemical exposure.

The structural design involves multiple seals, O-rings or gluing processes to ensure that the connection points maintain a waterproof barrier when plugged in or disconnected.

Ningbo Goshining Communication Technology Co., Ltd. monitors the production process through modern management technology and continues to absorb the latest global design concepts, such as using nano-coating technology to enhance material durability, so that the product performs better underwater or in extreme climates.

Question 3: How is the standard evaluation system for waterproof connectors divided?

Answer:

The international standard system is mainly based on IP coding. The numbers after IP represent the dustproof level and waterproof level respectively. For example, IP67 means complete dustproof and no leakage within 30 minutes of immersion in 1 meter of water.

Specifications such as IEC 60529 define test methods, including water spray, immersion and pressure tests, to ensure that connectors are certified in simulated real-world scenarios.

Specific industry standards such as ISO 16750 in the automotive field or MIL-STD-810 for military use require higher protection to adapt to vibration or shock environments.

Ningbo Goshining Communication Technology Co., Ltd. relies on advanced equipment to perform rigorous testing, continuously introduces international manufacturing technology to optimize the certification process, ensures that products meet global standards, and meets the diverse needs of industries, communications and other fields.

Question 4: What are the main application areas of waterproof connectors, and their industry impact?

Answer:

Widely used in communication infrastructure, such as base station antennas and optical fiber equipment, to ensure that signal transmission is not interfered with in rain, snow or high humidity environments, and prevent network interruptions.

The industrial automation field relies on it to protect production line sensors and control modules, reduce failure rates in humid workshops or outdoor scenes, and improve production efficiency.

In new energy vehicles and charging pile systems, waterproof connectors prevent water from entering the battery system and short-circuiting, ensuring overall safety and endurance.

Medical equipment such as portable monitors require a sterile waterproof environment to avoid contamination risks and ensure patient safety.

Ningbo Goshining Communication Technology Co., Ltd. combines the latest global design concepts to develop customized solutions, optimizes the supply chain through modern management technology, quickly responds to the needs of various industries, and promotes the innovative application of waterproof connectors in emerging fields such as 5G and IoT.

Question 5: What are the core advantages of Ningbo Goshining Communication Technology Co., Ltd. in the research and development of waterproof connectors?

Answer:

Relying on advanced production equipment, including high-precision molds and automated assembly lines, we achieve high consistency and low defect rate in mass production, ensuring the long-term reliability of connectors under extreme conditions.

Modern management technology integrates digital monitoring systems to track production data and quality control in real time, shorten the R&D cycle and improve product iteration efficiency.

Continuously introduce the latest design concepts in the global industry, such as bionic sealing structures or smart materials, combined with international manufacturing technologies such as German precision processes, so that products lead the market in waterproof level.

By absorbing international cutting-edge technologies, the company promotes the application of environmentally friendly materials and energy efficiency optimization, reduces carbon emissions, while maintaining cost competitiveness, and enables customers to achieve sustainable development in the global market.