Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

Waterproof Patch cord Supplier

Waterproof Patch cord uses standardized connectors and factory-tested components to ensure the reliability and consistency of the fiber optic network. This consistency reduces performance fluctuations caused by field operations while improving the stability of the network.

Waterproof Patch cord adopts a fully sealed box design, and maintenance operations can be performed without opening the box. This design not only improves the safety of the equipment, but also reduces the risk of failure caused by improper operation.

Waterproof Patch cord is suitable for a variety of network environments, including indoor and outdoor scenarios. Its modular design and flexible component combination enable it to meet deployment needs in different scenarios.

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom Waterproof Patch cord Supplier and OEM Waterproof Patch cord Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

As a core component in the optical fiber communication system, the performance and reliability of waterproof patch cords directly affect the stability and life of the network. Ningbo Goshining Communication Technology Co., Ltd. occupies a leading position in the research and development and manufacturing of waterproof patch cords with advanced production equipment, standardized manufacturing processes and complete testing instruments.

Question 1: What is the basic structure and functional principle of waterproof patch cords?

Waterproof patch cords are specially designed optical fiber connectors used to ensure the stability and continuity of signal transmission in humid or harsh environments. Its core function is to prevent moisture, dust and other external contaminants from invading the optical fiber interface, thereby avoiding signal attenuation or system failure. The structure of waterproof patch cords includes optical fiber core, protective sleeve, waterproof sealing ring and connector head. Among them, the sealing ring is made of corrosion-resistant materials (such as silicone or fluororubber), and a multi-layer barrier is formed through precision pressing technology to effectively block water vapor penetration. At the same time, the internal optical fiber adopts a low-loss design to ensure that the optical signal is transmitted within a loss range of less than 0.2dB/km. During the manufacturing process, Ningbo Goshining Communication Technology Co., Ltd. uses advanced automated production lines and standardized assembly processes to ensure that the sealing and optical performance of each patch cord meet international standards. For example, its technical management team has optimized the design of the waterproof structure through experienced professionals, so that the patch cord can still work stably under the IP68 protection level.

Question 2: In which application scenarios do waterproof patch cords play a key role, and how are their advantages reflected?

Waterproof patch cords are widely used in outdoor communication infrastructure, data centers, industrial automation systems, and marine engineering, and are especially important in humid, rainy or high humidity environments. Its core advantage is to provide reliable moisture and corrosion resistance to avoid signal interruption or equipment damage caused by environmental factors. In outdoor base station deployment, waterproof patch cords can resist rain and moisture erosion to ensure that the high-speed transmission of 5G networks is not affected; in submarine optical cable systems, its sealing design prevents seawater penetration and extends the service life of equipment by more than 20 years. In addition, waterproof patch cords also support fast installation and maintenance, achieve plug-and-play through standardized interfaces, and reduce network failure rates. Ningbo Goshining Communication Technology Co., Ltd. combines its own complete testing instruments, such as high-precision optical testers and environmental simulation cabins, to strictly verify these application scenarios. Through standardized manufacturing processes, the company ensures that the patch cord maintains stable performance in a wide temperature range of -40°C to 85°C to meet the needs of different climatic conditions.

Question 3: What are the key technologies and quality assurance measures for manufacturing high-quality waterproof patch cords?

The manufacturing of high-quality waterproof patch cords involves precision engineering and strict quality control, with the core being material selection, sealing process and performance testing. First, high-purity quartz optical fiber and weather-resistant polymer materials are selected to ensure the mechanical strength and optical properties of the patch cord; second, the sealing process uses laser welding or injection molding technology to form a seamless waterproof layer to prevent any microporous leakage. During the manufacturing process, environmental durability tests, including salt spray tests, wet heat cycles and vibration tests, must be passed to verify the reliability of the patch cord under extreme conditions. Ningbo Goshining Communication Technology Co., Ltd. relies on advanced production equipment such as fully automatic fiber cutting machines and spectrum analyzers to achieve efficient and consistent manufacturing. Its standardized manufacturing process includes multi-stage testing, from raw material storage to finished product shipment, all using non-destructive testing methods such as OTDR (optical time domain reflectometer) to detect signal loss. The company's technical management team is composed of experienced professionals. Through continuous research and development, the company optimizes waterproof technology, such as introducing nano-coating to enhance waterproofness and ensure that patch cords comply with international standards such as Telcordia GR-326.

Question 4: How does Ningbo Goshining Communication Technology Co., Ltd.'s innovation and practice in the development of waterproof patch cords promote industry progress?

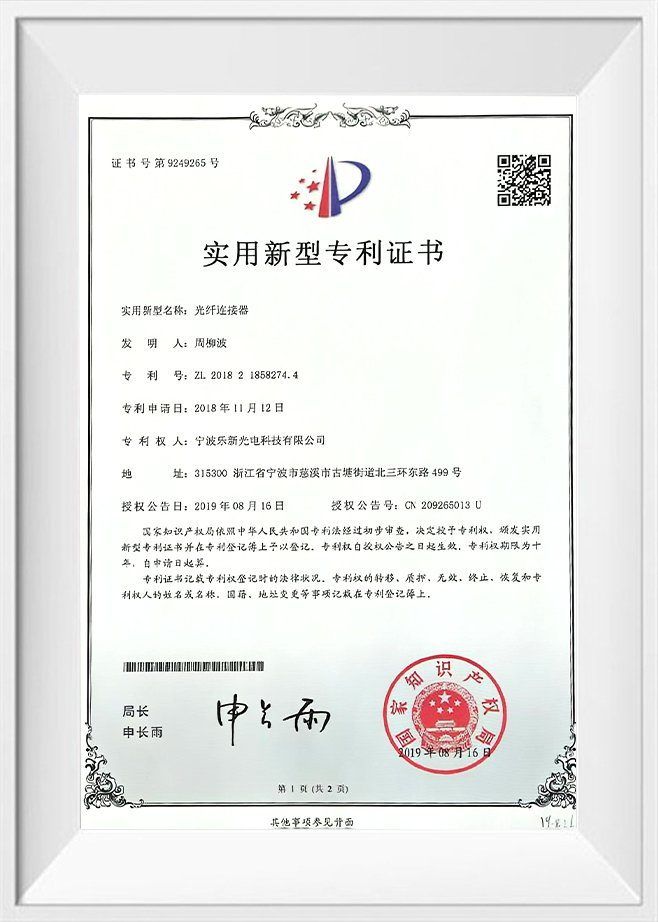

Ningbo Goshining Communication Technology Co., Ltd.'s innovative practices in the field of waterproof patch cords are reflected in its continuous investment in research and development and manufacturing optimization. The company is committed to the research and development of optical fiber products. Through the professional experience of the technical management team, it has developed a number of patented technologies, such as enhanced waterproof interface design and low-loss optical fiber formula. These innovations solve the aging problem of traditional patch cords in long-term use and improve product life and performance consistency. In terms of manufacturing, the company uses advanced automation equipment to achieve large-scale production, while ensuring the quality traceability of each batch of patch cords through standardized process management. For example, its testing instruments include high-resolution microscopes and spectrometers for real-time monitoring of the waterproof performance and optical parameters of patch cords. Ningbo Goshining Communication Technology Co., Ltd. has also promoted industry standardization through its practice. By participating in international forums and cooperation projects, it has applied waterproof patch cord technology to the construction of smart cities and the Internet of Things, helping customers reduce operation and maintenance costs by more than 20%. The company's professional team and resource integration have enabled waterproof patch cords to reach new heights in reliability, environmental protection and cost-effectiveness.