Product

- Pre-Connectorized ODN Solution

- Fiber Optic Fast Connector

- Fiber Optic PLC Splitter

-

Fiber Optic Patch Cord

- SC series Fiber Optic Patch cord

- LC Series Fiber Optic Patch cord

- FC Series Fiber Optic Patch cord

- ST Series Fiber Optic Patch cord

- OM1/2 Fiber Optic Patch cord

- OM3 Fiber Optic Patch cord

- OM4 Fiber Optic Patch cord

- Armored Series Fiber Optic Patch cord

- E2000 Series Fiber Optic Patch cord

- Pigtail Fiber Optic Patch cord

- 12 Multi Colors Fiber Optic Patch cord

-

Fiber Optic Cable

- Fiber Optic Distribution Box

- Fiber Optic Splice Closure

-

Fiber Optic Terminal Box

-

ODF Fiber Optic Distribution Frame

- Fiber Optic Accessories

- Fiber Optic Equipment&Tool

Fiber Optic Fusion Machine Supplier

Fiber Optic Fusion Machine is a critical link in the fiber optic network, used to accurately connect the two ends of the fiber optic cable to ensure seamless signal transmission and long-term reliability.

High precision and low loss: Fiber Optic Splice technology fuses the fiber end faces through arc heating to form a permanent connection with extremely low signal reflection loss and high transmission efficiency.

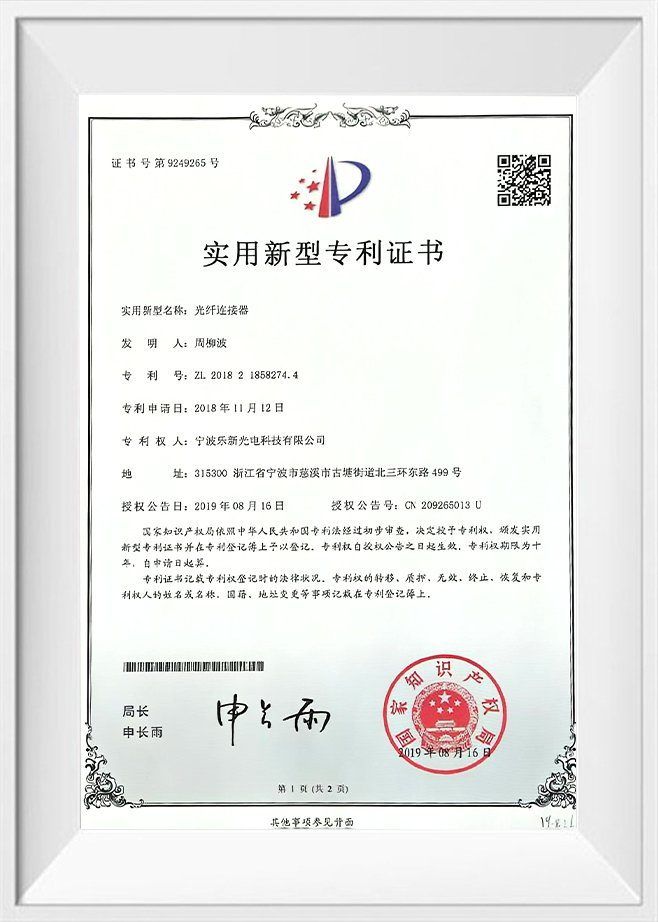

Ningbo Goshining Communication Technology Co., Ltd. is an enterprise that designs, produces, and sells a full range of fiber optic products with high-quality and first-class services, which enable us to meet all customers' demands and offer one-stop service. Ningbo Goshining Communication Technology Co., Ltd is a professional Custom Fiber Optic Fusion Machine Supplier and OEM Fiber Optic Fusion Machine Company, our products include Fiber Optic Fast Connector, Patch Cord, PLC Splitter, Cables, Distribution Box, Splice Closure, and Terminal Box etc. We also offer Customization services to help develop your own brand.

-

Feb 20, 2026_GoshiningAn OM3 fiber optic patch cords are high-performance multimode fiber optic patch cords that support high-speed data transmission (10G, 40G, and even 100G). They feature long transmission distances, high bandwidth, and strong compatibility, a...Read More

-

Feb 13, 2026_GoshiningFiber optic patch cords are essential connection components in fiber optic communication systems, and their performance directly affects network transmission quality and stability. So, how do you test fiber optic patch cords to ensure their...Read More

-

Feb 06, 2026_GoshiningIn fiber optic communication systems, LC and FC fiber optic connectors are two very common interface types. Simply put, LC fiber optic connectors are small and high-density, making them more suitable for high-port-density equipment; while F...Read More

As the core equipment for the construction and maintenance of optical communication networks, fiber fusion splicers undertake the key task of permanent and precise connection of optical fibers. In modern communication scenarios such as fiber to the home (FTTH), 5G fronthaul, and data center interconnection, the working quality of the fusion splicer directly determines the transmission performance of the entire optical fiber link.

The fusion splicer realizes the molecular-level fusion of optical fibers, forming a nearly perfect continuous waveguide structure, with a typical fusion point reflection loss better than -70dB; secondly, the precision fusion technology avoids the gaps and misalignments introduced by mechanical connectors, reducing the insertion loss to less than 0.05dB; finally, the automated fusion process greatly improves the construction efficiency, and skilled operators can complete 60-80 high-quality fusion points per hour, which is more than 3 times faster than traditional methods.

The fiber fusion splicer adopts the core direct alignment technology, captures the fiber end face image simultaneously through a high-resolution CCD camera and an infrared imaging system, and uses a machine vision algorithm to analyze the core position in real time. The high-end model is equipped with a six-motor drive system (two each for the X/Y/Z axis), which improves the core alignment accuracy to within 0.05 microns, equivalent to 1/1000 of the diameter of a human hair.

It only takes 15 seconds from fiber insertion to completion of fusion splicing: ① Fiber cut end face detection (0.5 seconds); ② Pre-alignment and cleaning discharge (2 seconds); ③ Fiber core precision alignment (3 seconds); ④ Main fusion discharge (1.5 seconds); ⑤ Loss estimation and strength test (3 seconds); ⑥ Heat shrink tube protection (5 seconds). The entire process is controlled in real time by the built-in processor without manual intervention.